I-10MM UKUYA KU-130MM Ukusakaza Ibhola Lensimbi Lokugaya I-Ball Mill Metal Mines kanye Nezitshalo zikasimende

Incazelo yomkhiqizo

Inqubo yokukhiqiza

Ibhola lokuphonswa, elibizwa nangokuthi i-casting grinding ball, lenziwa nge-scrap steel, scrap metal, nezinye izinto ezilahliwe. Izinto ezibalulwe ngenhla zincibilike kakhulu futhi ziqhuba umsinga oqhubekayo ngemva kokushisisa. Phakathi nesigaba sokuncibilika, inani elikhulu lezakhi zensimbi ezifana ne-vanadium, insimbi kanye ne-manganese kuqala zengezwa kugesi we-flue ukuze kuzuzwe isivuno esifiselekayo nesinqunywe kusengaphambili. Lezi zakhi zingakwazi ukuthela insimbi encibilike kakhulu ibe yimodeli yomugqa wokukhiqiza wesitshalo sokwenza insimbi.

Isicelo

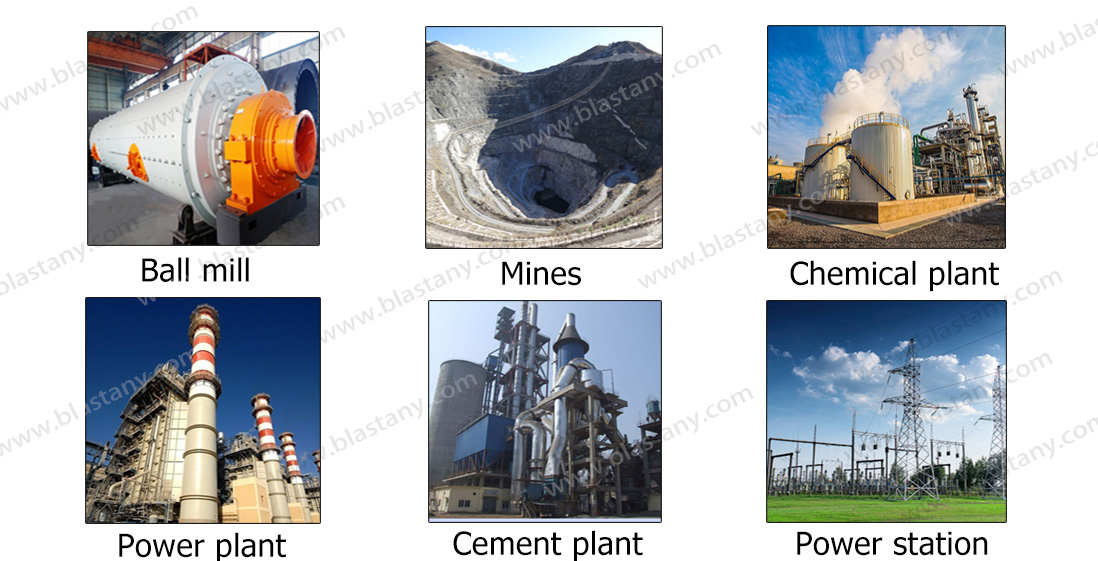

I-Casting Steel Ball ingasetshenziswa kakhulu ezinhlelweni ezahlukahlukene, kufaka phakathi

Imboni yesihlabathi sikasilika/Imboni kasimende/Imboni yamakhemikhali/Isikhungo samandla/Izimayini/Iziteshi zikagesi

/Izimboni zamakhemikhali/Isigayo sokugaya/Isigayo sebhola/Isigayo samalahle

Ukwethulwa kwemikhiqizo yebhola lensimbi

Amabhola ensimbi e-Chrome angamabhola emidiya agayayo aqukethe amaphesenti athile e-chromium, futhi ahlukaniswa ngawo abe amabhola ensimbi asakazwa nge-chromium aphezulu, amabhola ensimbi e-chromium amaphakathi kanye namabhola ensimbi asakazwa nge-chromium ephansi. Amabhola ensimbi e-chromium ahlukaniswe Amabhola Ensimbi Ephezulu Ye-Chromium, Amabhola Ensimbi e-Chromium Cast emaphakathi kanye namabhola ensimbi e-Chromium Cast aphansi. Ngesici sokuqina okuphezulu, ukugqoka okuphansi, nokuphuka okuphansi, amabhola okugaya insimbi asetshenziswa kakhulu embonini kasimende, imboni yezimayini, imboni ye-metallurgical, imboni yokuphehla amandla kanye nomkhakha wokwakha.

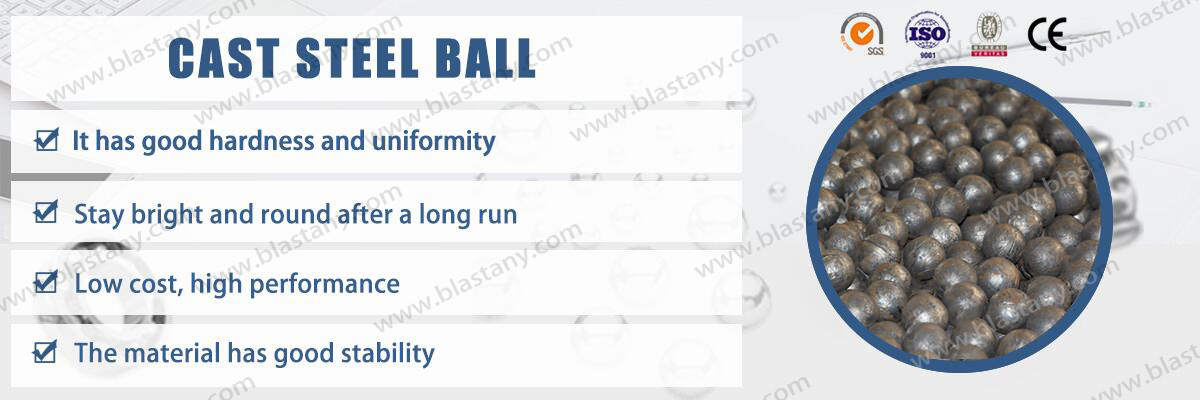

Izici ze-Cast Grinding Steel Ball

1, Izinto zokusetshenziswa zonke zinezinsalela zensimbi, eziqukethe ithusi, i-molybdenum, i-nickel nezinye izakhi zensimbi eziyigugu, ezingathuthukisa ngempumelelo ukwakheka kwe-matrix yebhola lensimbi.

I-2, Imikhiqizo yethu ikhiqizwa isithando somlilo sikagesi esiphakathi nendawo esingaqinisekisa ngempumelelo ukuqina kwento. Amabhola akulula ukuwaxebuka futhi awonakele ngesikhathi sokusetshenziswa. Ngisho ingahlala ikhanya futhi iyindilinga ngemva kokusebenza isikhathi eside.

I-3, Ulayini wokukhiqiza uwoyela wokucisha uwoyela osezingeni eliphezulu kakhulu wamukelwa ukwelashwa okushisa, oqinisekisa ubulukhuni obuhle nokufana kwemikhiqizo.

Izindlela ezintathu zokwenza amabhola ensimbi

1. Izindlela ezintathu zokukhiqiza ibhola lensimbi

Kunezinhlobo ezintathu zezinqubo zokukhiqiza amabhola ensimbi: ukulingisa, ukufoja, nokugingqa.

(1) Ukusakaza: Ikhwalithi yamabhola ensimbi ecijile kakhulukazi incike kokuqukethwe kwe-chromium. Eminyakeni yamuva nje, ukukhuphuka kwentengo ye-chromium, ukuvikelwa kwemvelo, nezinye izici kuye kwaholela ekwenyukeni kwezindleko zamabhola ensimbi.

(2) Ukuqamba: Ukusebenzisa insimbi ephezulu ye-manganese njengempahla eluhlaza, izando zokubumba zomoya kanye nokubunjwa kwebhola kusetshenziswa ukwenza amabhola ensimbi. Amabhola ensimbi afojiwe anenhlanganisela enengqondo ye-high-carbon, manganese, chromium, nezinye izakhi ze-alloy, futhi anokuqina okuqinile ekwelashweni kokushisa kokukhiqiza, umehluko omncane wokuqina phakathi kwangaphakathi nangaphandle, kanye nomehluko wevelu yomthelela, okwenza amabhola omgunyathi abe namandla kunamabhola aphonswe.

(3) Ukugingqika: Kusetshenziswa izinsimbi ze-manganese eziphezulu njengezisetshenziswa zokusetshenziswa, amabhola ensimbi enziwa umshini wokugaya u-skew onamarola asontekile.

| Into | Ukwakhiwa Kwekhemikhali(%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

| I-chrome ephezulu phonsa amabhola e-gri nding | ZQCr12 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 11-13 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 |

| ZQCr15 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 14-17 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 | |

| ZQCr20 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤0.10 | ≤0.08 | 0-2.0 | 0-1.0 | 0-1.5 | |

| ZQCr26 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤0.10 | ≤0.08 | 0-2.5 | 0-2.0 | 0-1.5 | |

| Ibhola lokugaya le-chrome ephakathi ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 | 0.2-1.0 | 6.0-10 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | 0-1.5 |

| Amabhola okugaya ane-chrome ephansi | ZQCr2 | 2.0-3.6 | 0.3-1.5 | 0.2-1.0 | 1.0-3.0 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | |

Amapharamitha aphezulu wokusakaza we-chromium (Ipharamitha yebhola le-Chrome Eliphezulu)

| Ububanzi bokuzisholo | Isisindo sebhola elilodwa ngokwesilinganiso(g) | Ubuningi/MT | Ukuqina kobuso(HRC) | Ukuhlolwa komthelela wokukhuthazela (Izikhathi) |

| φ15 | 13.8 | 72549 | > 60 | > 10000 |

| φ17 | 20.1 | 49838 | > 10000 | |

| φ20 | 32.7 | 30607 | > 10000 | |

| φ25 | 64 | 15671 | > 10000 | |

| φ30 | 110 | 9069 | > 10000 | |

| φ40 | 261 | 3826 | > 10000 | |

| φ 50 | 510 | 1959 | > 10000 | |

| φ60 | 882 | 1134 | > 10000 | |

| φ70 | 1401 | 714 | > 10000 | |

| φ80 | 2091 | 478 | >58 | > 10000 |

| φ90 | 2977 | 336 | > 10000 | |

| φ100 | 4084 | 245 | > 8000 | |

| φ120 | 7057 | 142 | > 8000 | |

| φ130 | 8740 | 115 | > 8000 |

Izigaba zemikhiqizo