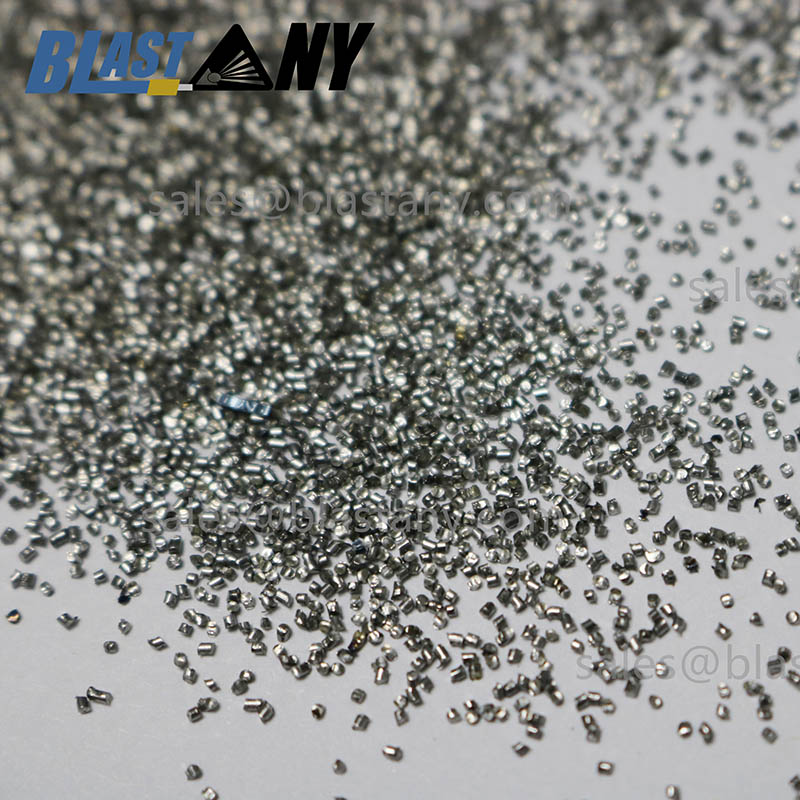

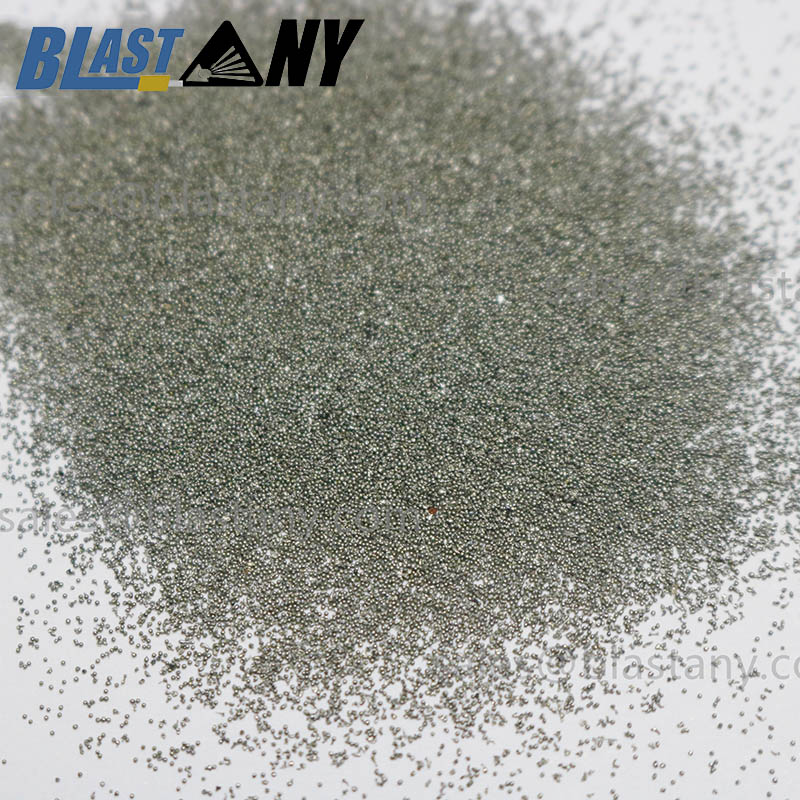

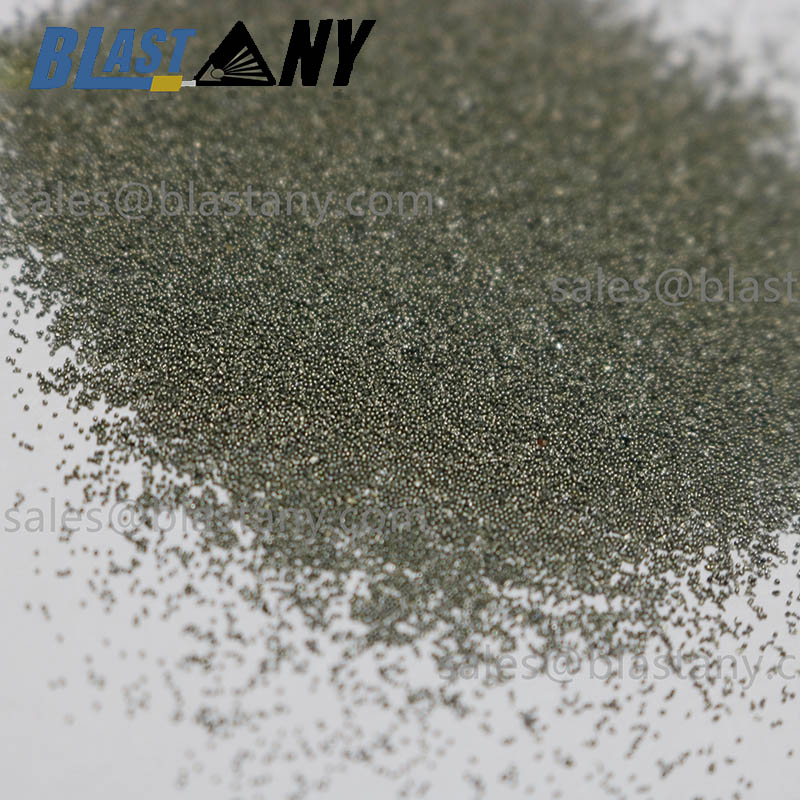

Ukudutshulwa kwensimbi engagqwali nge-atomization kwakha ubuchwepheshe

Inkambu yesicelo

1.Ukuqedwa komhlaba kwe-aluminium zinc kufa ukuphonsa nokuhlanzwa komhlaba kwe-aluminium sand casting. Ukufafaza kwemabula yemabula nokupholizwa. Ukuhlanza nokuqeda i-Alloy Steel Casting Great Surpace Oxide Scale, i-Aluminium Alloy block injini nezinye izingxenye ezinkulu zokufa, ukwelashwa kwemabula kokwelashwa kanye nokwelashwa kwe-antiskid.

2.I-Aluminium Zic Die Casting, Ukuhlanza Okungaphezulu Kokuphonsa Okunembile, Ukuqina Okungaphezulu Ngaphambi Kokuhlanganiswa Okukhethekile, Ukucwengeka kwesifutho sephrofayili ye-aluminium ukususa imigqa ye-aluminium ye-aluminium yokususa indawo yepayipi ye-aluminium ye-aluminium, kanye nokucwengeka kwesifutho esicwebezelayo se-stainless steralver kanye ne-valve engenasici.

3. Hlanza amathuluzi okuphonsa amakhaza, ama-chromium plies afa ngokufa namathayi, avuselele ikhava yepompo ye-supercharger ye-amobile, aqinise i-starter kanye nentwasahlobo ye-starter, bese uchofoza indawo yezitsha zensimbi engagqwali.

4.I-Aluminium zinc die casting, ibhokisi lenjini yezithuthuthu, ikhanda lesilinda, i-carburetor, igobolondo lepompo yamafutha enjini, ipayipi lokudla, ukukhiya imoto. Ingaphezulu lengcindezi ephansi yokufa kwesondo le-wheel wheel izohlanzwa futhi iqedwe ngaphambi kokupenda. Ukuqedwa komhlaba kanye nokuhlanza kwe-Copper Aluminium Steming Izingxenye Izingxenye, Ukutshalwa Kwezimali Ngokuphonsa Izingxenye Zensimbi Engagqwali, njll.

Amapharamitha Ezobuchwepheshe

| Umklamo | Ikhwalithi | Ikhwalithi engu-430 | |

| Ukwakheka kwamakhemikhali% | C | 0.08-1.0 | <0.2 |

| Si | 0.4-1.2 | <1.5 | |

| Mn | 0.35-1.2 | 0.8-1.2 | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 | 15-17 | |

| Ni | I-5-8% | 0 | |

| Ubunzima | HRC40-50 | HRC35-50 | |

| Incekusana | I-7.00 g / cm3 | ||

| Ukufongiwa | auntenitic | Isikali | |

| Ukubonakala | -Pholile Izinhlayiya eziyize = 0% Izinhlayiya eziyize = 0% | ||

| Ukuthayipha | 14-18 # / 16-20 # / 20-25 # / 25-30 # / 30-30 # / 30- 40 # / 40-70 # / 70-70 # / 140-270 # | ||

| Ukufaka ndawonye | I-TON TOW ku-pallet ehlukile nethani ngalinye lihlukaniswe ngamaphakethe angama-25kg. | ||

| Ukuqina | 27000 ~ 28000 Times | ||

| Incekusana | I-7.0g / cm3 | ||

| Isicelo | Isetshenziselwa ikakhulukazi ukuqeda ukudonswa kwemali okuphonsanayo nangaphezulu kwe-aluminium die casting, i-zinc alloy die casting kanye ne-magnesium alloy die casting; Ukuqedwa komhlaba wokuphonsa okunembile, ukusakaza insimbi engagqwali kanye neviki lendawo; Ukwenza ingilazi, ukuhlanza okungaphezulu nokuncipha okuhlukahlukene kokufa kokufa. | ||

Isicelo

| Ukuthayipha | Ububanzi obunconyiwe bokusebenzisa |

| 14-18 # | Hlanza amathuluzi okuphonsa amakhaza, i-chromium planical ifa ngokuthola amathayi, lungisa ikhava yepompo ye-supercharger ye-amotobile yemoto, qinisa amagiya anembile kanye nentwasahlobo ye-Starter, bese ufafaza indawo yensimbi engagqwali. |

| 16-20 # | I-Aluminium Zic Die Casting, Ukuhlanza Okungaphezulu Kokuphonsa Okunembile, Ukuqina Okungaphezulu Ngaphambi Kokuhlanganiswa Okukhethekile, Ukucwengeka kwesifutho sephrofayili ye-aluminium ukususa imigqa ye-aluminium ye-aluminium yokususa indawo yepayipi ye-aluminium ye-aluminium, kanye nokucwengeka kwesifutho esicwebezelayo se-stainless steralver kanye ne-valve engenasici. |

| 20-25 # | I-Aluminium zinc die casting, ibhokisi lenjini yezithuthuthu, ikhanda lesilinda, i-carburetor, igobolondo lepompo yamafutha enjini, ipayipi lokudla, ukukhiya imoto. Ingaphezulu lengcindezi ephansi yokufa kwesondo le-wheel wheel izohlanzwa futhi iqedwe ngaphambi kokupenda. Ukuqedwa komhlaba kanye nokuhlanza kwe-Copper Aluminium Steming Izingxenye Izingxenye, Ukutshalwa Kwezimali Ngokuphonsa Izingxenye Zensimbi Engagqwali, njll. |

| 25-30 # | I-Aluminium zinc die casting surface Ukuqeda, Ukuhlanzwa komhlaba kwe-aluminium Ingaphezulu lemabula yokufakelwa lifafazwa futhi litholwe. |

| 30-40 # | Ngaphezu komsebenzi we-WG40, ingaphezulu lokuphonswa kwensimbi engagqwali libushelelezi futhi lihle. Ukwelashwa okusolayo kokukholelwa kwensimbi ye-alloy. Ukuqedwa kwemabula yemabula yemabula yemabula kanye nokwelashwa kwe-antiskid. |

| 40-70 # | I-High alloy Steel Casting Great Great Skin ongide, i-aluminium alloy block kanye nezinye izingxenye ezinkulu zokuhlanza zokuhlanza nokuqeda, ukwelashwa okungaphezulu kwemabula kokwelashwa kanye nokwelashwa kwe-anti-skid. |

| 70-140 # 140-270 # | Ingaphezulu lokuphonswa kwensimbi okwakhekile liyamiswa ngaphambi kokuhlanganisa, izimoto ezinamasondo, ukwelashwa kwe-enjini, imikhiqizo ye-granite nezinyathelo zemabula okulwa nokwelashwa kwe-anti-skid. |

Ubukhamulo

| Isikrini. | Syschensise MM | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 | 70-140 | 140-270 |

| 14 | 1.4 | 0.0555 |

|

|

|

|

|

|

|

|

| 16 | 1.18 | 0.0469 |

|

|

|

|

|

|

|

|

| 18 | 1 | 0.0394 |

|

|

|

|

|

|

|

|

| 20 | 0.85 | 0.0331 |

|

|

|

|

|

|

|

|

| 25 | 0.71 | 0.0278 |

|

|

|

|

|

|

|

|

| 30 | 0.6 | 0.0234 |

|

|

|

|

|

|

|

|

| 35 | 0.5 | 0.0197 |

|

|

|

|

|

|

|

|

| 40 | 0.425 | 0.0165 |

|

|

|

|

|

|

|

|

| 50 | 0.3 | 0.0117 |

|

|

|

|

|

|

|

|

| 70 | 0.212 | 0.0083 |

|

|

|

|

|

|

|

|

| 100 | 0.15 | 0.0059 |

|

|

|

|

|

|

|

|

| 140 | 0.106 | 0.0041 |

|

|

|

|

|

|

|

|

| 270 | <0.05 | <0.0019 |

|

|

|

|

|

|

|

|

Imikhakha Imikhakha