I-AISI1010/1015/1085 Ibhola lensimbi ephezulu/ephansi ye-carbon 0.8 mm – 50.8 mm Ibhola lensimbi le-Carbon lamasondo amaketanga amabhayisikili

Incazelo yomkhiqizo

Ibhola Lensimbi Eliphansi Lekhabhoni.

| Okubalulekile | AISI1010/1015 |

| Ububanzi besayizi | 0.8mm-50.8mm |

| Ibanga | I-G100-G1000 |

| Ukuqina | HRC:55-65 |

Incazelo Yomkhiqizo

Izici:

Zinozibuthe, Amabhola Ensimbi Ekhabhoni anongqimba olungaphezulu (ukuqina kwekesi), kuyilapho ingxenye yangaphakathi yebhola ihlala i-soft metallographic tructure iyi-ferrite, iphakheji ngokuvamile inamafutha. Ngokujwayelekile i-electroplating uma ingaphandle , ingagqitshwa ngezinc , igolide , i- nickel , i- chrome nokunye . zibe nokusebenza okuqinile kokungagugi .Ukuqhathanisa : ukumelana nokuqina nokuba lukhuni akukuhle kunokuthwala ibhola lensimbi ( I - HRC ye-GCr15 steel ball ingama - 60- 66 ) : ngakho , ukuphila kufushane uma kuqhathaniswa .

Isicelo:

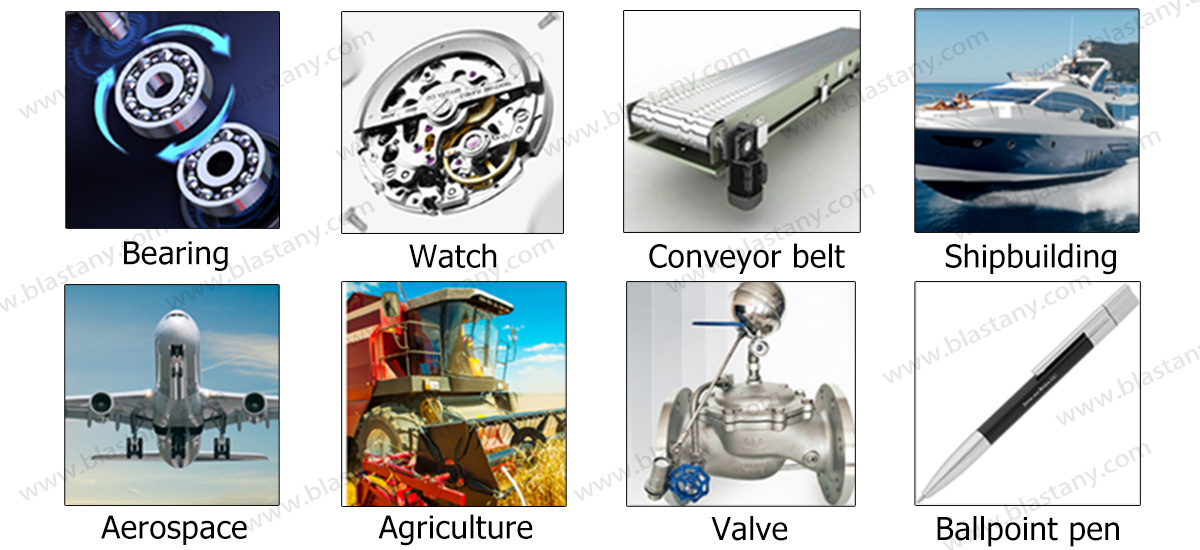

I-1010/1015 carbon steel ball iyibhola lensimbi elijwayelekile, linenani eliphansi, ukunemba okuphezulu nokusetshenziswa okubanzi. Isetshenziselwa ibhayisikili, amabherengi, isondo leketanga, umsebenzi wezandla, ishalofu, ibhola eliguquguqukayo, izikhwama, i-hardware encane, ingase futhi isetshenziselwe ukuhlikihla enye i-medium.Castors, Dressers' Bearings, Locks, Oilers And Grease Cups, Skates.drawers Slides And Window Rolling Bearings, Amathoyizi, I-Finikiters.

| UHLOBO LOKUSEBENZA | C | Si | Mn | P (MAX.) | S (MAX.) |

| I-AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

| I-AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0.60 | 0.04 | 0.05 |

Ibhola Lensimbi Eliphezulu Lekhabhoni

| Okubalulekile | I-AISI1085 |

| Ububanzi besayizi | 2mm-25.4mm |

| Ibanga | I-G100-G1000 |

| Ukuqina | HRC 50-60 |

Incazelo Yomkhiqizo

Izici:

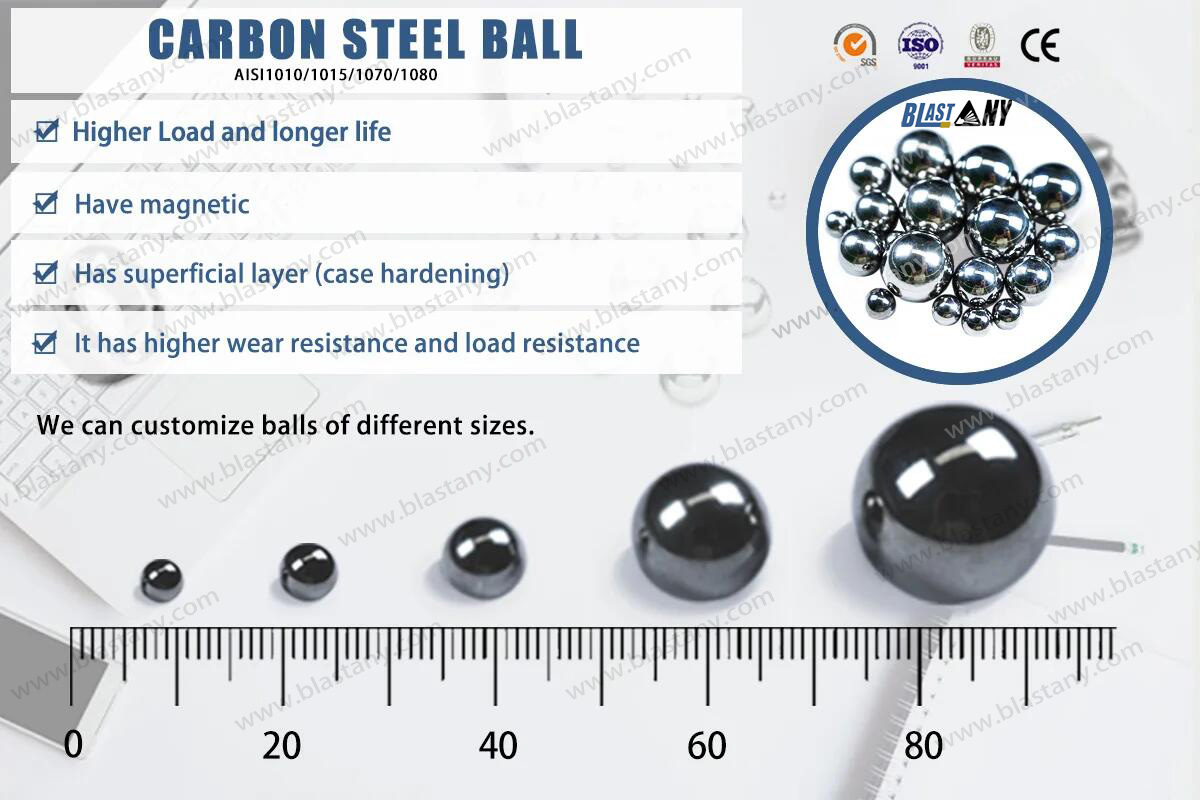

I-AISI1070/1080 I-Carbon Steel Balls, & Amabhola ensimbi ekhabhoni ephezulu anenzuzo emangalisayo ngokuya ngenkomba yobulukhuni obuphelele, ecishe ibe ngu-60/62 HRC futhi inikeze ukuguga okuphakeme nokumelana nomthwalo uma kuqhathaniswa namabhola ensimbi aqinile ekhabhoni aphansi.

(1)Ukuqina kwenhliziyo

(2)Ukumelana okuphansi nokuhlasela okulimazayo

(3)Umthwalo Ophakeme nempilo ende kunebhola eliphansi le-carbon steel

Isicelo:

Izinsiza zebhayisikili, amabhola efenisha amabhola, iziqondiso ezishelelayo, amabhande okuthutha, amasondo omthwalo osindayo, amayunithi asekela amabhola. Ama-bearings anemba aphansi, ibhayisikili nezingxenye zezimoto, ama-agitators, ama-skates, imishini yokupholisha neyokugaya, ama-bearings anemba eliphansi.

| UHLOBO LOKUSEBENZA | C | Si | Mn | P (MAX.) | S (MAX.) |

| I-AISI 1070 (C70) | 0.65-0,70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| I-AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

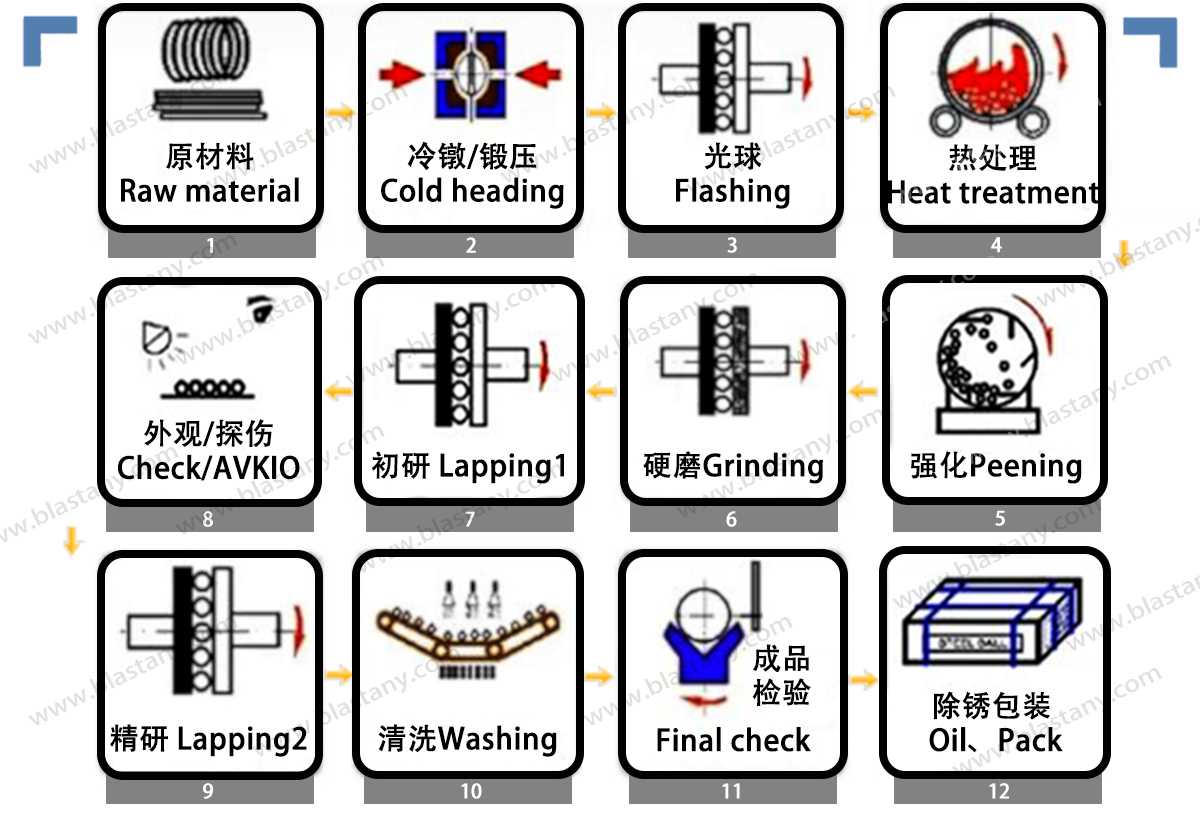

Inqubo yokukhiqiza

Inqubo Yokukhiqiza Yemikhiqizo Yebhola Elinembile

1.Impahla Yomthetho

Ezigabeni zayo zokuqala, ibhola liqala ngocingo noma ngesimo senduku. Ukulawulwa kwekhwalithi kuhamba ngokuhlolwa kwe-metallurgic ukuze kuqinisekiswe ukuthi ukwakheka kwezinto kungaphakathi kwebanga elamukelekayo.

2.Isihloko

Ngemva kokuba impahla eluhlaza isidlulile ekuhlolweni, bese idliswa ngesihloko esinesivinini esikhulu. Lokhu kwakha amabhola amabi kakhulu.

3.Ukukhanya

Inqubo ekhanyayo ihlanza amabhola anezihloko ukuze abukeke abushelelezi.

4.Ukwelashwa Kokushisa

Inqubo yokushisa ephezulu kakhulu lapho amabhola akhanyayo afakwa kuhhavini yezimboni. Lokhu kwenza ibhola libe lukhuni.

5.Ukugaya

Ibhola liyagaywa lilingane nosayizi webhola lokugcina.

6.Ukubhebha

Ukugxusha kwebhola kuliletha ezingeni elifisayo lokugcina. Lena inqubo yokugcina yokwenza futhi ithola ibhola ngaphakathi kokubekezelelwa kwebanga.

7.Ukuhlola Okokugcina

Ibhola libe selilinganiswa kahle bese lihlolwa yi-Quality Control ukuze kuqinisekiswe izinga eliphezulu kakhulu.

Izigaba zemikhiqizo