Ukwelashwa okuphezulu okuphezulu kwe-White Aluminium Oxide Grit

Incazelo Yomkhiqizo

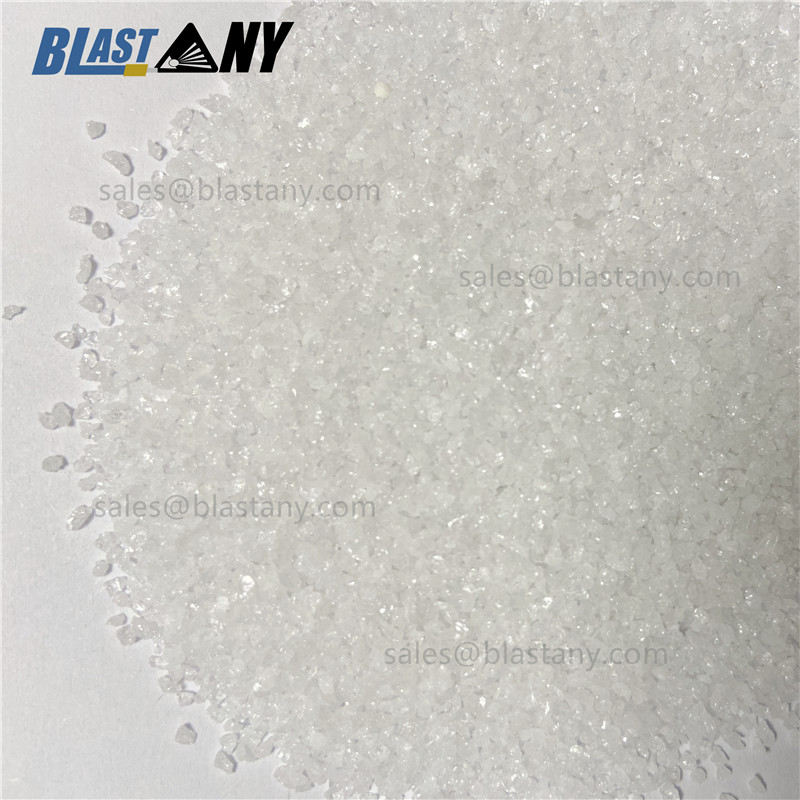

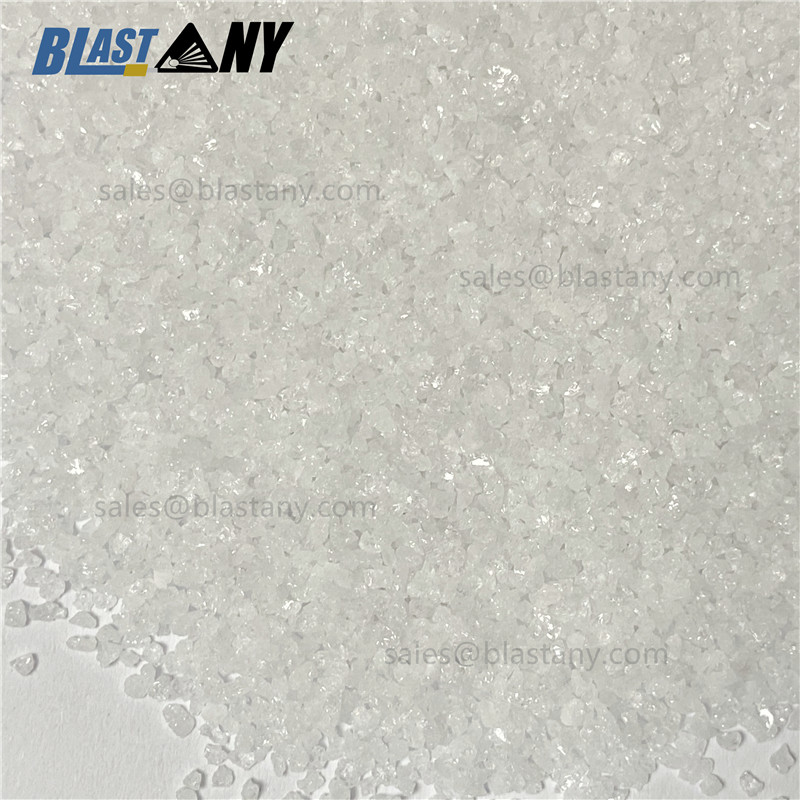

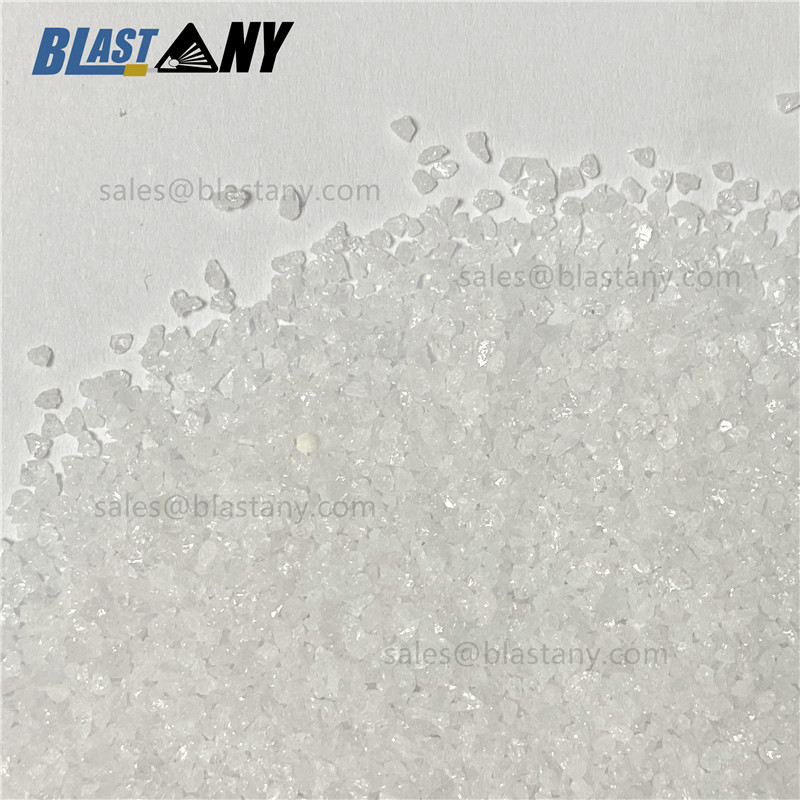

I-Junda White aluminium oxide grit iyibanga elingu-99.5% elihlanzekile kakhulu lemidiya eqhumayo. Ukuhlanzeka kwale midiya kanye nezinhlobonhlobo zosayizi begrit abatholakalayo kuyenza ifaneleke kuzo zombili izinqubo zendabuko ze-microdermabrasion kanye nokhilimu bokucweba bekhwalithi ephezulu.

I-Junda White aluminium oxide grit iyi-abrasive ebukhali kakhulu, ehlala isikhathi eside engaqhunyiswa kabusha izikhathi eziningi. Ingenye ye-abrasive esetshenziswa kakhulu ekuqedeni ukuqhuma nokulungiswa kwendawo ngenxa yezindleko zayo, ubude bokuphila, nobulukhuni. Kakhulu kunezinye izinto ezivame ukusetshenziswa eziqhumisayo, izinhlamvu ze-aluminium oxide ezimhlophe zingena futhi zinqume izinsimbi eziqinile kakhulu ne-sintered carbide.

I-Junda White aluminium oxide blasting media inezinhlobonhlobo zezinhlelo zokusebenza, okuhlanganisa ukuhlanza amakhanda enjini, ama-valve, ama-piston nama-turbine blades endizeni nasezimbonini zezimoto. I-aluminium oxide emhlophe nayo iyisinqumo esihle kakhulu sokulungiselela indawo eqinile yokudweba.

I-Junda White aluminium oxide iqukethe i-silica yamahhala engaphansi kuka-0.2% ngakho-ke iphephile ukuyisebenzisa kunesihlabathi. Usayizi wegrit uyavumelana futhi usike ngokushesha kakhulu kuneminye imidiya yokuqhunyiswa kwesihlabathi, okushiya indawo ebushelelezi.

Imingcele Yezobuchwepheshe

| Ukucaciswa kwegrithi ye-Aluminium Oksidi Emhlophe | |

| I-Mesh | Usayizi Wezinhlayiyana Omaphakathiinombolo yemeshi encane, igridi ibe mahholo |

| 8 Mesh | 45% 8 mesh (2.3 mm) noma ngaphezulu |

| 10 Mesh | 45% 10 mesh (2.0 mm) noma ngaphezulu |

| 12 Mesh | 45% 12 mesh (1.7 mm) noma ngaphezulu |

| 14 Mesh | 45% 14 mesh (1.4 mm) noma ngaphezulu |

| 16 Mesh | 45% 16 mesh (1.2 mm) noma ngaphezulu |

| 20 Mesh | 70% 20 mesh (0.85 mm) noma ngaphezulu |

| 22 Mesh | 45% 20 mesh (0.85 mm) noma ngaphezulu |

| 24 Mesh | 45% 25 mesh (0.7 mm) noma ngaphezulu |

| 30 Mesh | 45% 30 mesh (0.56 mm) noma ngaphezulu |

| 36 Mesh | 45% 35 mesh (0.48 mm) noma ngaphezulu |

| 40 Mesh | 45% 40 mesh (0.42 mm) noma ngaphezulu |

| 46 Mesh | 40% 45 mesh (0.35 mm) noma ngaphezulu |

| 54 Mesh | 40% 50 mesh (0.33 mm) noma ngaphezulu |

| 60 Mesh | 40% 60 anezikhala (0.25 mm) noma ngaphezulu |

| 70 Mesh | 45% 70 mesh (0.21 mm) noma ngaphezulu |

| 80 Mesh | 40% 80 mesh (0.17 mm) noma ngaphezulu |

| 90 Mesh | 40% 100 mesh (0.15 mm) noma ngaphezulu |

| 100 Mesh | 40% 120 mesh (0.12 mm) noma ngaphezulu |

| 120 Mesh | 40% 140 mesh (0.10 mm) noma ngaphezulu |

| 150 Mesh | 40% 200 mesh (0.08 mm) noma ngaphezulu |

| 180 Mesh | 40% 230 mesh (0.06 mm) noma ngaphezulu |

| 220 Mesh | 40% 270 mesh (0.046 mm) noma ngaphezulu |

| 240 Mesh | 38% 325 mesh (0.037 mm) noma ngaphezulu |

| 280 Mesh | I-Median: 33.0 - 36.0 micron |

| 320 Mesh | 60% 325 mesh (0.037 mm) noma kakhudlwana |

| 360 Mesh | I-Median: 20.1-23.1 micron |

| 400 Mesh | I-Median: 15.5-17.5 micron |

| 500 Mesh | I-Median: 11.3-13.3 micron |

| 600 Mesh | I-Median: 8.0-10.0 micron |

| 800 Mesh | I-Median: 5.3-7.3 micron |

| 1000 Mesh | I-Median: 3.7-5.3 micron |

| 1200 Mesh | I-Median: 2.6-3.6 micron |

| Pumzila igama | Izici Zomzimba Ezijwayelekile | I-Proximate Chemical Analysis | ||||||

| Igridi ye-Aluminium oxide emhlophe | Umbala | Umumo Wokusanhlamvu | I-Crystallinity | Ukuqina | I-Gravity ethize | Ukuminyana kwenqwaba | I-Al2O3 | ≥99% |

| Emhlophe | I-Angular | Ikristalu eqinile | 9 moh | 3.8 | 106 lbs / ft3 | I-TiO2 | ≤0.01% | |

| I-CaO | 0.01-0.5% | |||||||

| MgO | ≤0.001 | |||||||

| Na2O | ≤0.5 | |||||||

| SiO2 | ≤0.1 | |||||||

| Fe2O3 | ≤0.05 | |||||||

| K2O | ≤0.01 | |||||||

Izigaba zemikhiqizo