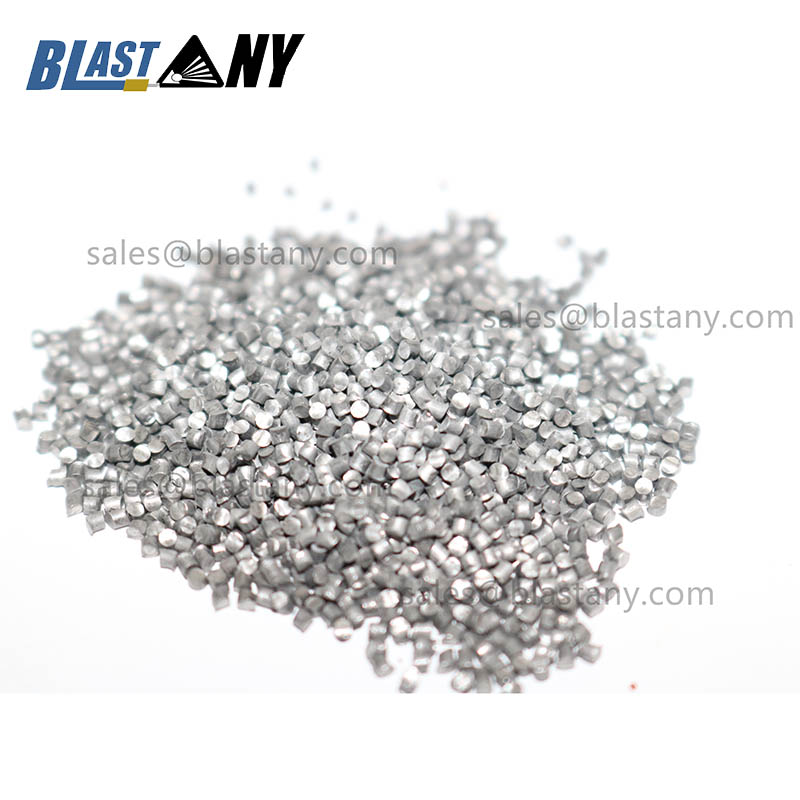

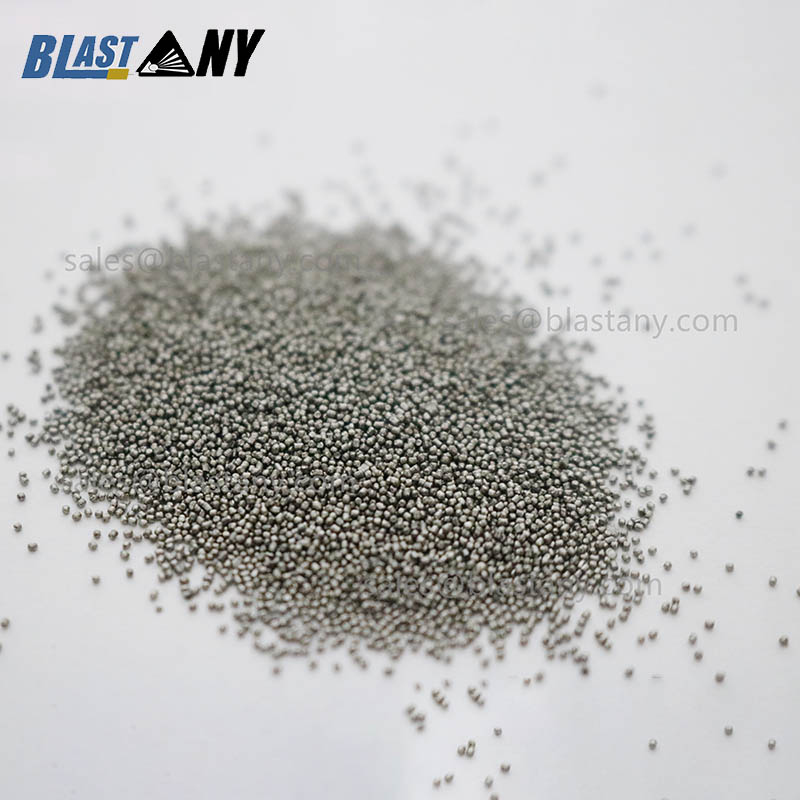

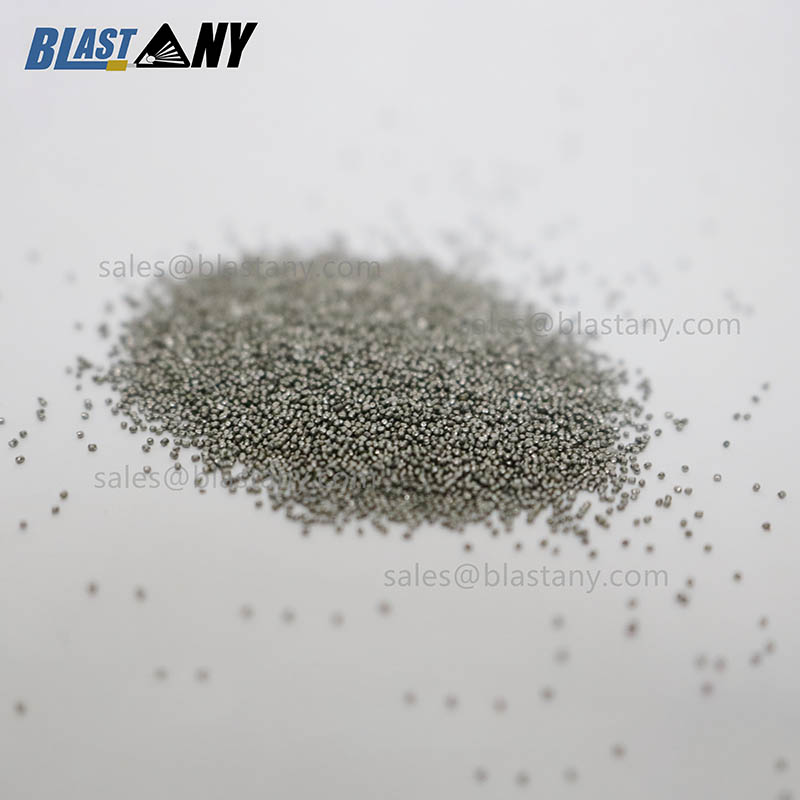

Amandla aphezulu ukumelana nokukhathala Cut Wire Shot

Uhlobo lwensimbi yokusika isibhamu

0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Ububanzi bokusetshenziswa kwamaphilisi okusika ucingo

1. Ukuqinisa ukusika ucingo lwensimbi: ukuqinisa ukuqhunyiswa kokudubula, ukuqinisa ukuqhuma kwezingxenye eziphathwe ukushisa, ukuqinisa ukuqhuma kwamagiya.

2. Ukuchama kocingo lwensimbi: ukuchama kwensimbi, ukuqhuma kwesihlabathi sensimbi, ukuqhuma kwesibhamu somkhumbi, ukuchama kwensimbi, ukuchama kwensimbi.

3. Ukuhlanza insimbi yensimbi: ukuhlanza ukuqhuma, ukuhlanza ukuqhuma kwesibhamu, ukuhlanza i-die casting, ukuhlanza ukuqhuma kwesibhamu, ukuhlanza ukuqhuma kwesibhamu, ukubunjwa kwesibhamu ukuqhumisa isihlabathi ukuhlanza amapuleti ensimbi, ukuhlanza insimbi, ukuhlanza insimbi, ukuhlanza insimbi ye-H, ukuhlanza isakhiwo sensimbi.

4. Intambo yensimbi yokusika idubula: ukuqhunyiswa kokudubula, ukucisha isibhamu, ukucisha isibhamu, ukucisha insimbi, ukukhwabanisa okucekela phansi ipuleti lensimbi, ukucekelwa phansi kwensimbi, ukucisha insimbi, uhlaka lwe-H lucekela phansi isakhiwo sensimbi.

5. I-steel wire cutting shot sand: ukwelashwa kwesihlabathi.

6. Steel wire shot cutting cutting pretreatment: enamathela pretreatment, enamathela pretreatment, surface pretreatment, umkhumbi pretreatment, isigaba steel pretreatment, steel pretreatment, steel pretreatment, steel isakhiwo pretreatment.

7. Ukudubula kocingo lwensimbi: ukuqhuma kwepuleti lensimbi, ukuqhuma kwensimbi, ukuqhuma kwensimbi.

Imishini esebenzayo yokusika ucingo lwensimbi

Insimbi yensimbi yokusika isetshenziselwa ukukhiqiza insimbi ngaphambi kokwelashwa, ulayini wokukhiqiza wensimbi ngaphambi kokwelashwa, ulayini wokukhiqiza wesakhiwo sensimbi, umshini wokudubula oqhumayo, imishini yokudubula, imishini yokudubula, umshini wokuqhumisa isihlabathi, imishini yokuqhumisa isihlabathi.

Imingcele Yezobuchwepheshe

| Imikhiqizo | Sika Wire Shot | |

| C | 0.45-0.75% | |

| Mn | 0.40-1.20% | |

| Ukwakheka Kwamakhemikhali | Si | 0.10-0.30% |

| S | 0.04% | |

| P | 0.04% | |

| Ukuqina okuncane | 1.0mm 51~53 HRC(525~561HV) | |

| I-Tensile Intensity | 1.0mm 1750–2150 Mpa | |

| Ukuminyana | 7.8g/cm3 | |

Izigaba zemikhiqizo