Amabhola ensimbi okugaya ayimithombo yokugaya kanye nezingxenye eziyinhloko zesigayo sebhola. Zingathinta ngqo ukusebenza kahle kokugaya kwayo yonke imboni yokucubungula insimbi kanye nekhwalithi yokugcina yomkhiqizo.

Phakathi nenqubo yokugaya, amabhola ensimbi okugaya asetshenziselwa ukuxuba nokugaya izinto (njengamaminerali, upende, namakhemikhali) abe izimpushana ezinhle.

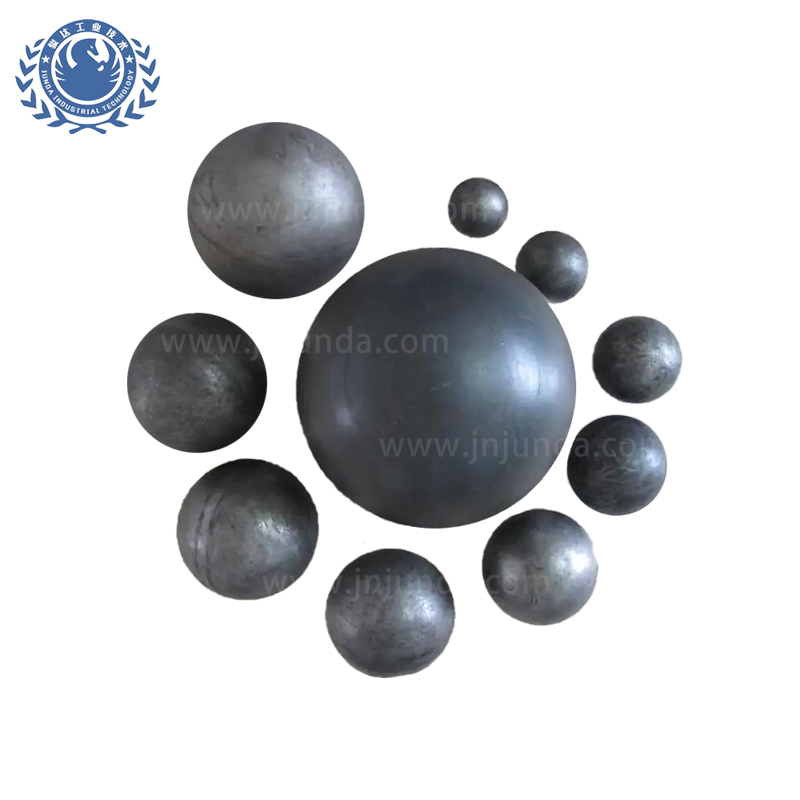

Izinhlobo zamabhola ensimbi okugaya

Njengoba amabhola ensimbi egayayo adinga ukumelana okuhle nokuhuzuka kanye nokuba namandla okwanele komthelela, futhi angeke ephuke, i-Fote Machinery yenze ukuhlolwa kokuqina, ukuhlola ukwakheka kwamakhemikhali kanye nokuhlolwa kwekhwalithi yangaphakathi yebhola ngalinye.

Ngokwenqubo yokukhiqiza, amabhola ensimbi yokugaya amabhola ezimayini ahlukaniswa abe amabhola ensimbi okugaya kanye namabhola ensimbi okugaya.

1. Forged ukugaya amabhola ensimbi

Ufuna ukusebenza kahle kokugaya okuphezulu? Okwezimayini zegolide noma zikasimende? Khona-ke ungakhetha amabhola ensimbi okugaya, atholakala kuzo zonke izigaba zokugaya.

Ibhola lensimbi elakhiwe nge-fote lingahlukaniswa libe yikhabhoni ephansi, ikhabhoni ephakathi, ibhola eliphezulu le-carbon steel esekelwe kumaphesenti ekhabhoni.

Okuqukethwe kwekhabhoni kungaphansi kuka-1.0%. Okuqukethwe kwe-chromium ngu-0.1%-0.5% (Ngokuvamile akuqukethe i-chromium).

2. Cast amabhola ensimbi okugaya

Njengolunye uhlobo lwemidiya yokugaya, amabhola ensimbi agayayo angahlinzeka nge-Cr (1% -28%), ukuqina (HRC40-66), kanye namabhola ensimbi asakazwa yi-Diameter (10mm-150mm).

Angahlukaniswa abe yi-chromium ephansi, i-chromium ephakathi, i-chromium ephezulu, ibhola lokugaya i-chromium ephezulu kakhulu (CR12% -28%).

Amabhola ensimbi e-Fote cast anaMANDLA AMABILI:

I-low crushing ratio: Ukumelana nokuphephuka nokuchotshozwa izikhathi ezingu-10 kunamanye amabhola afojiwe. Inombolo yemithelela yamabhola awayo ingafinyelela izikhathi ezingaphezu kuka-100,000. Izinga langempela lokuchotshozwa lingaphansi kuka-0.5%, eduze nokungachotshozwa.

Ukuqedwa kahle kwendawo: Ingaphezulu lebhola alivunyelwe ukuthi libe neziphambeko zokulingisa, njengokuqhekeka, izimbotshana ezisobala, izimbobo, izimbobo ezishwabene, ukufakwa okubandayo, isikhumba sendlovu, njll.

I-Forged VS Cast igaya amabhola ensimbi

Izinhlobo ezimbili zamabhola ensimbi anezinga elihlukile lokuguga, njengoba acutshungulwa yibhola lensimbi eligayayo: Ukucinywa kwamanzi kuvame ukusetshenziselwa ukubumba amabhola ensimbi, ngakho izinga lawo eliphukile liphezulu.

I-Cast grinding steel ball: Isebenzisa ukucisha izinga lokushisa eliphezulu kanye nokwelashwa okufudumele ukuze yenze amabhola okugaya aqine kakhulu futhi angagugi.

Ngakho-ke, ukuqhathaniswa kokumelana nokugqoka kuboniswe ngezansi:

Amabhola ensimbi agayayo > amabhola ensimbi afojiwe. Futhi phakathi kwamabhola ensimbi, ibhola eliphezulu le-chromium > ibhola le-chromium eliphakathi > ibhola le-chromium eliphansi.

Isikhathi sokuthumela: Jan-17-2024