Ubuhlalu bengilazi bubonisa "ubungani bobuso" okukhulu uma kuqhathaniswa namanye ama-abrasive amaningi, njenge-alumina, i-silicon carbide, negrit yensimbi. Lesi sici ngokuyinhloko sibangelwa izici zayo ezihlukile zomzimba namakhemikhali. Ubungane obuphezulu bobuhlalu bengilazi bubonakaliswa ekhonweni lokuhlanza noma lokupholisha izindawo ngendlela ephumelelayo kuyilapho kunciphisa umonakalo emsebenzini ngokwawo.

Okulandelayo yizici ezimbalwa ezibalulekile ezibangela lesi simo:

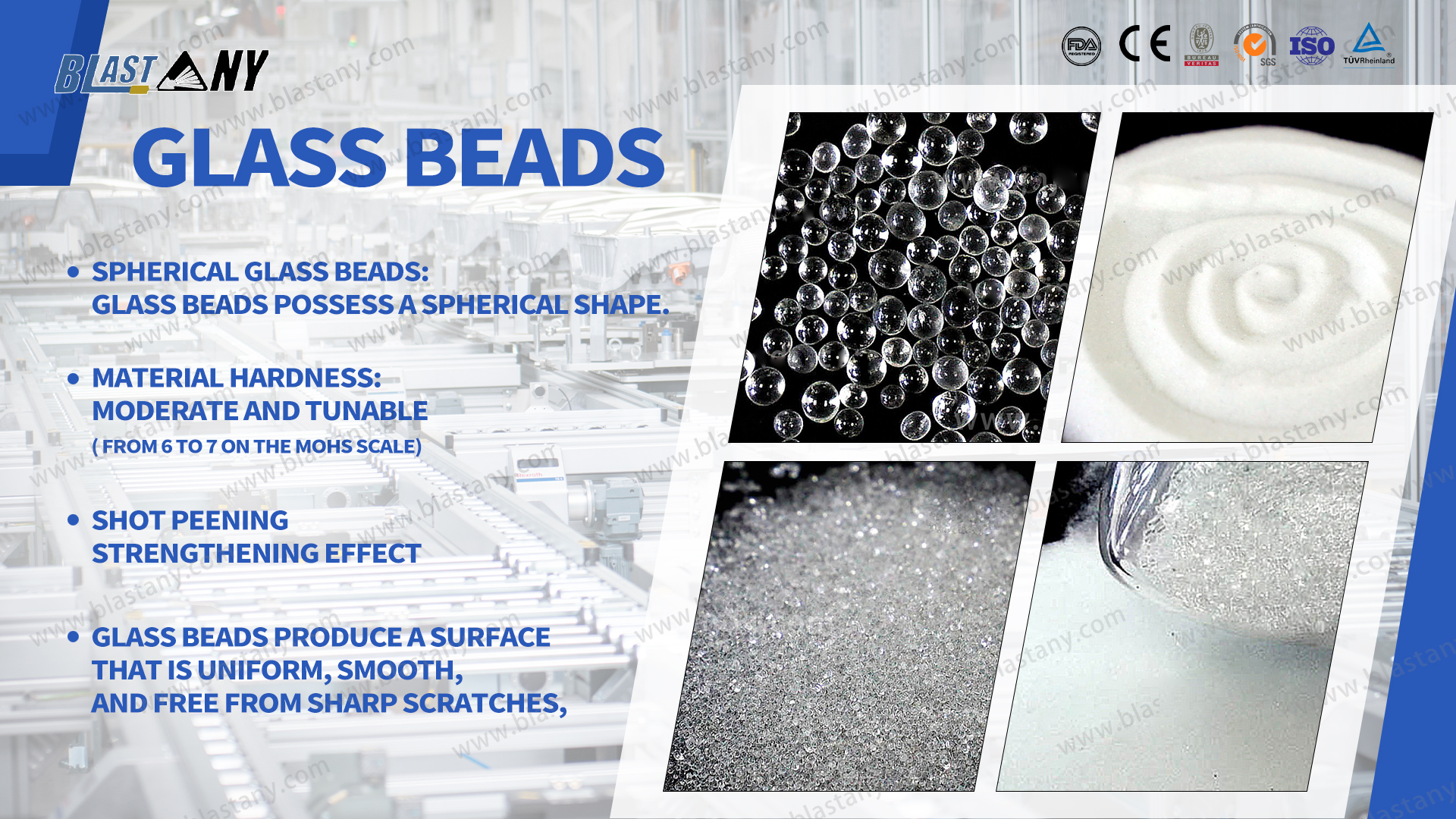

1.Umumo kanye nesakhiwo: I-Spherical vs. Angular

- Ubuhlalu Bengilazi Eyisiyingi: Ubuhlalu bengilazi bunomumo oyindilinga. Ngesikhathi senqubo ye-sandblasting ezindaweni zokusebenza, basungula othintana nabo bephoyinti. Le modi yokuxhumana iholela ekugxilweni kwengcindezi ephansi uma kuqhathaniswa. Isenzo sifana kakhulu nomphumela "wokuthepha" noma "wokugingqika", ikakhulukazi ukusebenzela ukususa ukungcola kwendawo entekenteke, njengezendlalelo zokugqwala namafilimu amadala kapende, ngaphandle kokungena ngokujulile kungcezu yokusebenza.

- Ama-Angular Abrasives: Ngokuphambene, ama-abrasives afana ne-brondum ensundu, i-steel grit, ne-copper slag ngokuvamile afaka imiphetho ebukhali nengavamile. Uma zisetshenziselwa ukuqhunyiswa kwesihlabathi, zenza ulayini noma amaphoyinti okuxhumana, okudala ingcindezi enkulu yendawo. Lokhu kufana namashizolo amaningi amancane aqopha phezulu.

Ukuma okuyisiyingi kobuhlalu bengilazi kugwema ngempumelelo ukusika nokubhoboza okubangelwa imiphetho ebukhali, ngaleyo ndlela kunciphisa ngokuphawulekayo ukuguga kwezingcezu zokusebenza futhi kunciphise ukwanda kokuqina kwendawo.

2.Ukuqina Kwezinto ezibonakalayo: Okumaphakathi futhi Okuthunazekayo

Ukuqina kobuhlalu bengilazi ngokuvamile busuka ku-6 kuye ku-7 esikalini se-Mohs. Leli zinga lokuqina lanele ukususa ngokuphumelelayo ukungcola okujwayelekile kwendawo, njengokugqwala (okunobunzima be-Mohs obungu-4 - 5) namafilimu okupenda amadala. Ngesikhathi esifanayo, ingaphansi noma iqhathaniswa nobulukhuni bezinto eziningi zensimbi.

3. Shot Peening Ukuqinisa Effect

Umthelela oyindilinga wobuhlalu bengilazi endaweni yensimbi ukhiqiza isendlalelo sokucindezeleka esifana nesomzuzu. Lesi sendlalelo sinikeza izinzuzo ezimbalwa:

- Ukumelana Nokukhathala Okuthuthukisiwe: Kuthuthukisa amandla okukhathala ezingxenyeni zensimbi, ukumelana ngokuphumelelayo nokuqalwa nokusakazwa kwemifantu.

- Ingozi Eyehlisiwe Yokugqwala Kwengcindezi: Ungqimba lwengcindezi olucindezelayo lunciphisa amathuba okugqwala kwengcindezi.

- I-Wear Resistance Ethuthukisiwe: Ngokwenza umsebenzi obandayo ube lukhuni ebusweni, kuthuthukisa ukumelana nokugqokwa kwempahla.

4. I-Surface Qeda

Ngenxa yokuma kwazo okuyisiyingi nezici zomthelela, ubuhlalu bengilazi bukhiqiza indawo efanayo, ebushelelezi, futhi engenazo imihuzuko ebukhali, evame ukubizwa ngokuthi “i-satin finish”. Lokhu kuqedwa kunikeza i-substrate efanelekile yokufafaza okulandelayo, ukunamathela, noma izinqubo ze-electroplating, okuqinisekisa ukunamathela okuqinile kokunamathela.

Ngokuphambene, ama-abrasive angama-angular adala isimo sendawo esimaholoholo esineziqongo nezigodi. Nakuba lokhu kungase futhi kuthuthukise ukunamathela ngezinga elithile, kudla izinto eziningi zokumboza futhi kuphumele ekubukekeni okungaphansi kobuhle.

Ngenxa yalezi zinzuzo, ubuhlalu bengilazi buvame ukusetshenziswa ezinhlelweni lapho ubuqotho be-substrate bubaluleke kakhulu, njengokucutshungulwa kwezingxenye ezinembayo, isikhunta, izingxenye ze-aerospace, imikhiqizo yensimbi engagqwali, kanye ne-aluminium alloy die-castings. Zimelela ukukhetha okuphelele kokufinyelela ibhalansi phakathi kokuhlanza indawo esebenzayo nokuvikelwa kwe-substrate.

Ukuze uthole ulwazi olwengeziwe, sicela ukhululeke ukuxoxa nenkampani yethu!

Isikhathi sokuthumela: Sep-18-2025