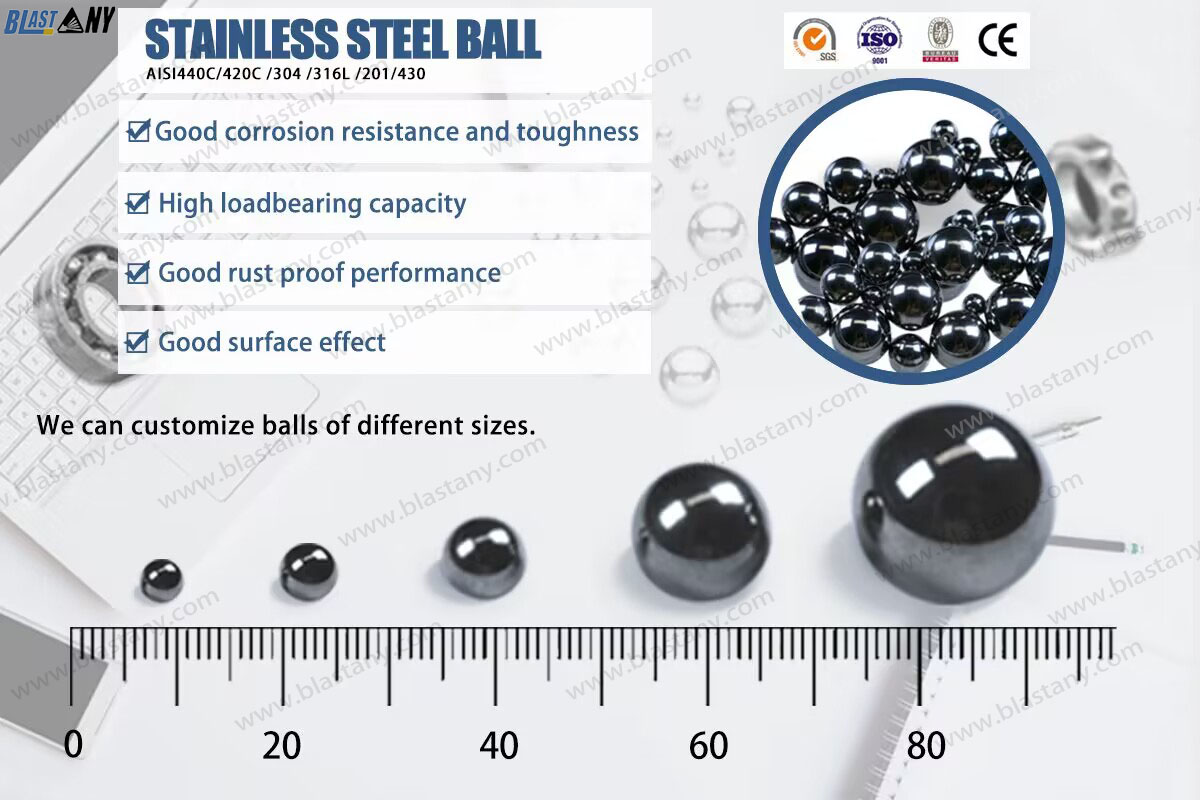

Ukunikezwa kwefekthri 0.35mm- 50.8mm HRC50-55 ukukhanya AISI304 316 430 440 ibhola lensimbi engagqwali elisetshenziswa ku-Bearing

Incazelo yomkhiqizo

Amabhola angagqwali ayakwazi ukumelana nokugqwala ngama-ejenti afana nezixazululo ze-oxidizing, amakhemikhali amaningi e-organic, izinto zokudla kanye nezixazululo ezibulala amagciwane.Ziyakwazi ukumelana ngokusesilinganisweni kuma- sulfuric acid.Izakhiwo ezingezona kazibuthe ezitholakala lapho ucelwa.Izicelo zifaka i-aerosol, izifutho, izindlela zokumpompa iminwe, izixube zomshini wobisi, imishini yokucubungula ukudla kanye nezicelo zezokwelapha.

I-AISI 440C Ibhola lensimbi engagqwali

Usayizi: 0.35mm-50.8mm

Ibanga:G10, G16, G40, G60, G100, G200.

Ukuqina: HRC56-58, Hartford 440C amabhola ensimbi engagqwali ayadluliswa ukuze asuse ukungcola kwensimbi yamahhala futhi enze kube lula ukwakheka okuzenzakalelayo kwefilimu yokuvikela engenzi lutho.

Magnetic: Insimbi ye-Martensitic, kazibuthe

Izici: ukunemba okuphezulu, ukumelana nokugqwala okuhle, ukugqwala okuqinile nokumelana nokugqoka.

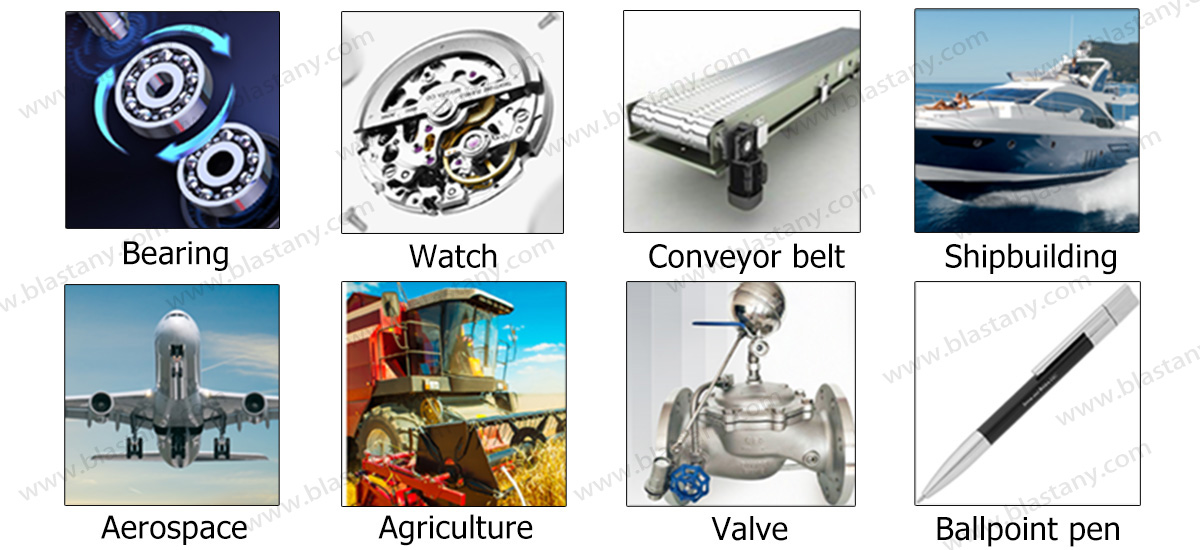

Izicelo:Amabheringi, izitembu, izingxenye ezithinta umshini, amavalvu, i-aerospace, ama-seal, okokusebenza kwesiqandisi, amathuluzi anemba kakhulu, njll.

| Ukwakheka kwamakhemikhali | ||||||||

| I-AISI 440C | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.95-1.10 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.60 | 16.0-18.0 | 0.75 | |

I-AISI 420C Ibhola lensimbi engagqwali

Usayizi: 0.35mm-50.8mm

Ibanga: G10-G1000

Ukuqina: HRC50-55

I-Magnetic:Insimbi ye-Martensitic, kazibuthe, Ikhono elihle lokulwa nokugqwala, ubulukhuni obuphezulu, amabhola ensimbi engenasici e-AISI 420 abonisa izici ezinhle zokugqoka nobulukhuni.Ubulukhuni obuncane kancane kanye nokumelana nokugqwala okukhulu, uma kuqhathaniswa no-440C.

Izici: Eyaziwa kakhulu ngokuthi insimbi engagqwali, ukumelana nokugqwala okuhle kanye nokuqina.

Izicelo: Zonke izinhlobo zemishini enembayo, amabheringi, izinto zikagesi, izinto zasendlini, izingxenye zezimoto, njll.

| I-AISI 420C(4Cr13) | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.36-0.43 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.60 | 12.0-14.0 | ≤0.60 |

430 ibhola lensimbi engagqwali

Ububanzi: 1MM-50.80MM

Ukuqina: HRC26

Ibanga: G10-G1000

Izici: intengo ephansi, ukumelana nokugqwala okubi.

Isicelo:izingxenyekazi zekhompyutha, imihlobiso, izesekeli, izimonyo, imboni, izimboni ezinezidingo eziphansi zokusebenza kwe-antirust.Ama-cosmetics agitators, i-nail polish nama-eyeliner, izishintshisi zokushisa, amathuluzi okulinganisa.namabhola e-valve.

| AISI 430 | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | - | 16.0-18.0 | - |

I-AISI 304 Ibhola lensimbi engagqwali

Usayizi: 0.5mm-63.5mm

Ibanga: G80-G500

Ukuqina: ≤HRC21

I-Magnetic: Insimbi ye-Austenitic, engeyona i-magnetic

Izici: ukumelana nokugqwala okuqinile, ukumelana nokugqwala okuhle.kusetshenziswe kabanzi, ukusebenza kahle kobufakazi bokugqwala, umphumela omuhle wendawo, isitifiketi sokuvikela imvelo.

Izicelo:Izinto zasendlini ezinjengamavalvu, amabhodlela eziqholo, i-nail polish, amabhodlela ezingane, izingxenye zezimoto, ama-air conditioner, izinto zikagesi, izimonyo, i-bearing slide, okokwelashwa, ubucwebe nezinye izimboni eziningi.

| Ukwakheka kwamakhemikhali | |||||||

| AISI 304 | C | Si | Mn | P | S | Ni | Cr |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-22.0 | |

I-AISI 316L Ibhola lensimbi engagqwali

Usayizi: 1.0mm-63.5mm

Ibanga: G80-G500

Ukuqina: ≤HRC26

I-Magnetic: Insimbi ye-Austenitic, engeyona i-magnetic

Izici: ezifanele kakhulu izimboni ezinezidingo eziphezulu zokulwa nokugqwala, nekhono lokulwa nokugqwala liqine kakhulu,Ukumelana kahle nokugqwala (ngaphandle kwe-chloridric acid),Ayiyona i-austenitic inox eqinile

Izicelo: I-AISI 316L yensimbi engagqwali ibhola ingasetshenziselwa imishini yezokwelapha, imboni yamakhemikhali, izindiza, i-aerospace, i-hardware yepulasitiki, ibhodlela lamakha, isifutho, ama-valve, upholishi wezinzipho, umshini, ukushintshwa, i-ayina, imishini yokuwasha, iziqandisi, ama-air conditioner, izinto zokwelapha ,izingxenye zezimoto, amabheringi, insimbi, ibhodlela.

I-AISI 316L Ibhola lensimbi engagqwali

| Ukwakheka kwamakhemikhali | ||||||||

| I-AISI 316L | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | |

Ukupakishwa Komkhiqizo

A) Ukupakisha kwangaphakathi: Ukupakisha okomile noma ukupakisha uwoyela kunikezwa ngokwezidingo zakho.

B) Ukupakisha kwangaphandle:

1)isigubhu sensimbi + ipulangwe lokhuni / lensimbi.

2) 25kg isikhwama se-poly + ibhokisi + i-pallet yokhuni noma ibhokisi lezinkuni.

ukupakisha ngokwezifiso.

Ipharamitha Yomkhiqizo

| Ibhola lethu Lensimbi Engagqwali lihlanganisa 440C 420C 304 316 201, Ukwakheka kweChemical kunjengokulandelayo | |||||||||

| Ukwakheka kwamakhemikhali (%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| Ibhola le-AISI440C SS | 0.95-1.2 | 16-18 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.75 | ≤0.6 | ---- |

| Ibhola le-AISI420C SS | 0.26-0.43 | 12-14 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.6 | ≤0.6 | ---- |

| Ibhola le-AISI304 SS | ≤0.08 | 18-22 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | ---- | 8-10 | ---- |

| Ibhola le-AISI316L SS | ≤0.08 | 16-18 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 2.0-3.0 | 12-15 | ---- |

| Ibhola le-AISI201 SS | ≤0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤0.045 | ≤0.03 | ---- | 0.35-0,55 | 1.82 |

| Ibhola le-AISI430 SS | ≤0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ---- | ---- | ---- |

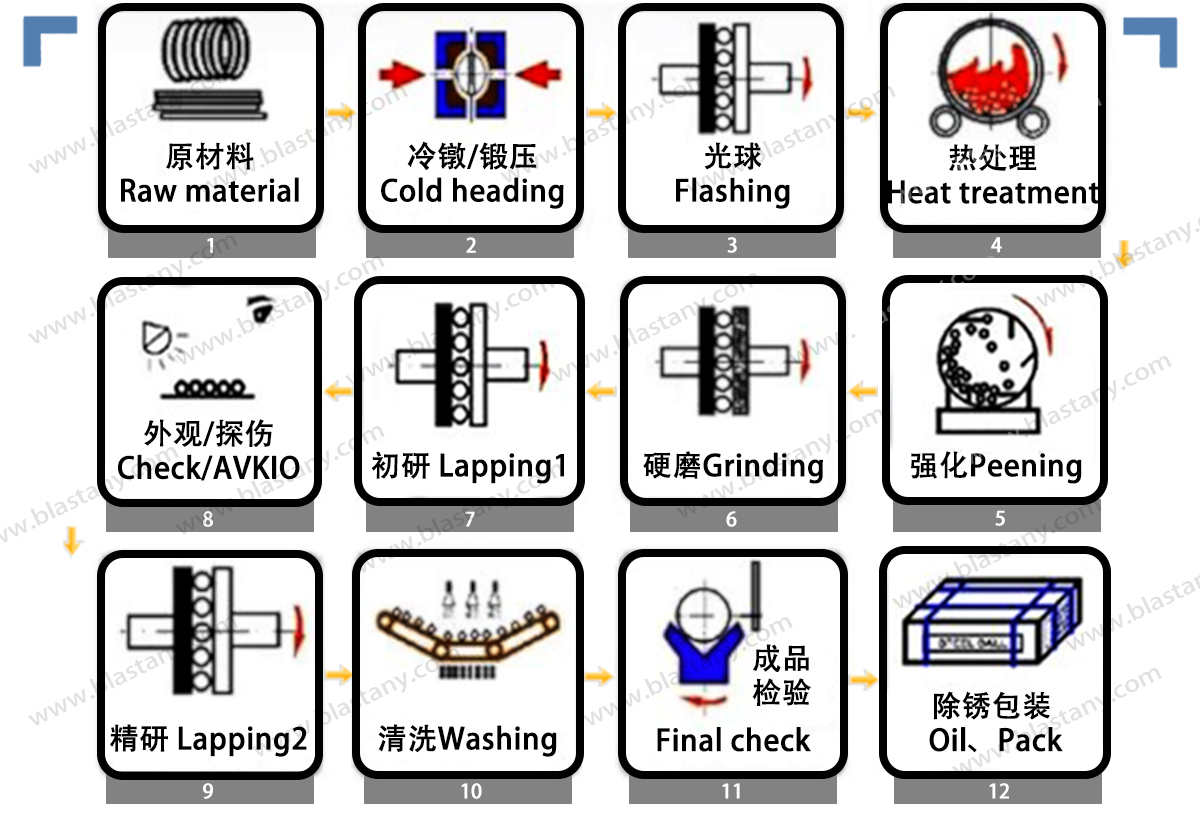

Ukukhiqiza Ukugeleza

Ukuhlolwa Kwezinto Ezingavuthiwe

Impahla eluhlaza iza ngendlela yocingo.Okokuqala, impahla eluhlaza ibhekwa abahloli bekhwalithi ukuze kutholakale ukuthi ikhwalithi isezingeni elifanele yini nokuthi zikhona yini izinto ezinokukhubazeka.Okwesibili, qinisekisa ububanzi futhi ubuyekeze izitifiketi zempahla eluhlaza.

Isihloko Esibandayo

Umshini wesihloko esibandayo usika ubude obucacisiwe bezinto zocingo zibe yi-cylindrical slugs.Ngemva kwalokho, ama-halves amabili ane-hemispherical yesihloko ayafa akha i-slug ibe yindilinga ecishe ibe yindilinga.Le nqubo yokubumba yenziwa ekamelweni lokushisa futhi inani elincane lezinto ezingeziwe lisetshenziselwa ukuqinisekisa ukuthi umgodi wokufa ugcwele ngokuphelele.Isihloko esibandayo senziwa ngesivinini esiphezulu kakhulu, ngesivinini esimaphakathi sebhola elilodwa elikhulu ngomzuzwana.Amabhola amancane aqondiswa ngesivinini samabhola amabili kuya kwamane ngomzuzwana.

Iyabaneka

Phakathi nale nqubo, ukwaziswa okweqile okwakhiwa eduze kwebhola kuzosuswa.Amabhola adluliswa izikhathi ezimbalwa phakathi kwamapuleti ensimbi amabili agqinsiwe asusa inani elincane lempahla eyeqile njengoba egingqika.

Ukwelashwa Kokushisa

Izingxenye zibe-ke kufanele ziphathwe ngokushisa kusetshenziswa izinqubo zokucisha nokushisa.Isithando somlilo esijikelezayo sisetshenziswa ukuze kuqinisekiswe ukuthi zonke izingxenye zinezimo ezifanayo.Ngemuva kokwelashwa kokushisa kokuqala, izingxenye zicwiliswa endaweni yokugcina amafutha.Lokhu kupholisa okusheshayo (ukucisha uwoyela) kukhiqiza i-martensite, isigaba sensimbi esibonakala ngokuqina okuphezulu kanye nezakhiwo zokugqoka eziphakeme.Ukufuthelana okulandelayo kunciphisa ingcindezi yangaphakathi kuze kube yilapho kufinyelelwa umkhawulo wokugcina wokuqina obekiwe wamabhereli.

Ukugaya

Ukugaya kwenziwa kokubili ngaphambi nangemva kokwelashwa kokushisa.Qeda Ukugaya (okubuye kwaziwe ngokuthi Ukugaya Kanzima) kusondeza ibhola ezidingweni zalo zokugcina.Ibanga lebhola lensimbi elinembayoiyisilinganiso sokunemba kwayo iyonke;lapho inombolo iphansi, ibhola linembe kakhudlwana.Ibanga lebhola lihlanganisa ukubekezelela ububanzi, ukuzungeza (i-sphericity) kanye nobukhulu obungaphezulu obubuye bubizwe ngokuthi ukuphela kwendawo.Ukwenziwa kwebhola eliqondile kuwumsebenzi wenqwaba.Ubukhulu belothi bunqunywa usayizi wemishini esetshenziselwa ukugaya nokuhlanganisa.

Ukubhuqa

I-Lapping ifana nokugaya kodwa inezinga eliphansi kakhulu lokususa izinto.I-Lapping yenziwa kusetshenziswa amapuleti amabili e-phenolic kanye ne-slurry e-abrasive enhle kakhulu njengothuli lwedayimane.Le nqubo yokugcina yokukhiqiza ithuthukisa kakhulu ubulukhuni bendawo.I-Lapping yenziwa ngenxa yokunemba okuphezulu noma amamaki ebhola anembe kakhulu.

Ukuhlanza

Umsebenzi wokuhlanza ube usususa noma iziphi izinto eziwuketshezi ezicutshungulwayo kanye nensalela yezinto eziqhumayo ohlelweni lokukhiqiza.Amakhasimende acela izidingo eziqinile zokuhlanza, njengalezo ezisemkhakheni we-microelectronics, izimboni zezokwelapha noma zokudla, angakwazi ukusizakala nge-Hartford Technologies izinketho zokuhlanza eziyinkimbinkimbi.

Ukuhlola Okubonakalayo

Ngemuva kwenqubo yokukhiqiza eyinhloko, amabhola ensimbi amaningi anembayo ahlolwa izikhathi eziningi zokulawulwa kwekhwalithi.Ukuhlolwa okubonakalayo kuyenziwa ukuze kubhekwe iziphambeko njengokugqwala noma ukungcola.

I-Roller Gauging

I-roller gauging iyinqubo yokuhlunga engu-100% ehlukanisa kokubili amabhola ensimbi anemba angaphansi nosayizi ongaphezu kosayizi.Sicela uhlole okuhlukile kwethuividiyo kunqubo yokukala i-roller.

Ikhwalithi yokulawula

Inqwaba yamabhola anembayo iyahlolwa ukuze kuqinisekiswe izimfuneko zebanga lokubekezelela ububanzi, ukuzungeza kanye nobulukhuni bomhlaba.Phakathi nale nqubo, ezinye izici ezifanele ezinjengokuqina, nanoma yiziphi izidingo ezibonakalayo nazo ziyahlolwa.

Izigaba zemikhiqizo