Ubuhlalu bengilazi obunama-refractive indexes angu-1.9 no-2.2

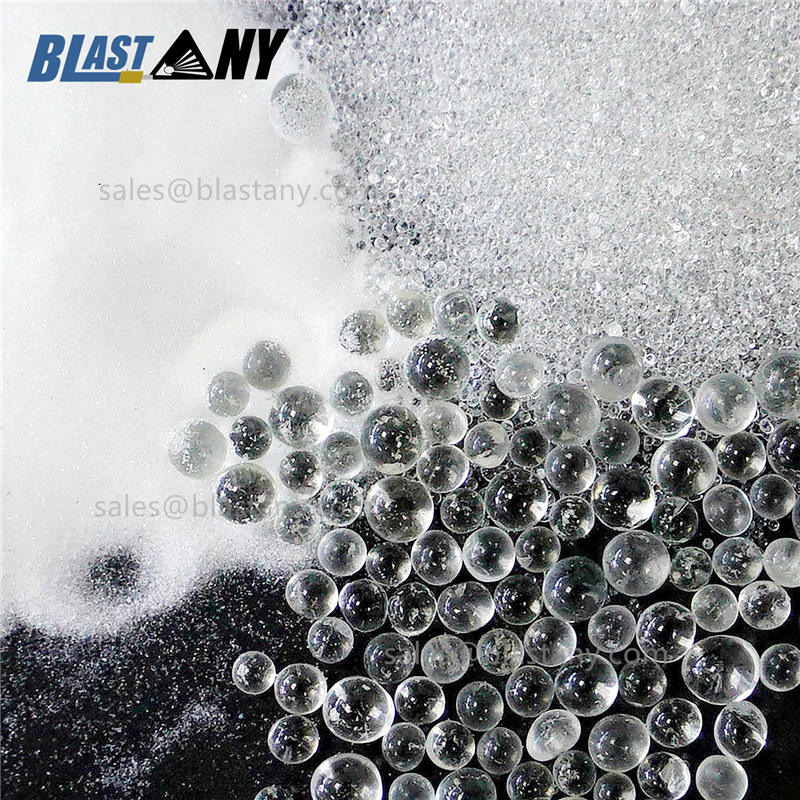

Sandblasting Glass Ubuhlalu

I-Junda glass bead iwuhlobo lokuqhunyiswa kwe-abrasive ukuze kuqedwe phezulu, ikakhulukazi ukulungisa izinsimbi ngokuzishelela. Ukuqhunyiswa kobuhlalu kunikeza ukuhlanzeka okuphezulu kwendawo ukuze kukhishwe upende, ukugqwala nokunye okunamathelayo.

Inqubo yokuqhumisa ubuhlalu bengilazi ivumelana nemvelo futhi ayinamakhemikhali futhi ingasetshenziswa ukuthola amaphutha e-weld kanye ne-solder. Izinzuzo zokusebenzisa i-glass bead blasting zihlanganisa:

●Izinhlobonhlobo ezinkulu zamabanga atholakalayo emisebenzi namaphrofayili ahlukene.

●Ayiphazamisi kuma-coatings ngoba ayisebenzi.

●Ayishiyi zinsalela noma ukungcola okushumekiwe, futhi futhi ayibangeli noma yikuphi ukuguquka kwendawo yobukhulu.

●Ukumelana nokugqwala okuthuthukisiwe kanye nekhono lokushelela amaphutha endaweni.

●Ayikho i-silica ye-crystalline ebonakalayo.

Isebenza kanjani?

Ukuqhunyiswa kobuhlalu be-Junda Glass empeleni kusebenza ubuhlalu bengilazi obuhle bosayizi abahlukahlukene ngamazinga ahlukahlukene okucindezela. Ama-glass sphere amancanyana aphumela endaweni ebushelelezi kuyilapho ama-sphere amakhulu akhiqiza ukuthungwa okungaphezulu.

Ubuhlalu bengilazi abususi noma iyiphi insimbi eyisisekelo noma bushumeke phezulu. Izokhiqiza ukuqeda okungcono, okufanayo okufanayo ngenkathi futhi yengeza ukukhanya noma ukukhanya engxenyeni.

Inezinhlelo zokusebenza ezahlukahlukene, kufaka phakathi:

●Ukuqeda: Ingasetshenziswa ezinhlobonhlobo zezinto ezibonakalayo, ezihlanganisa izinsimbi, ingilazi, ipulasitiki kanye nerabha.

●Ukuhlanza: Ngaphandle kokubangela ukushintsha kobukhulu obuphezulu, ukuqhunyiswa kobuhlalu bengilazi kususa/kuhlanza izinto ezingaphandle.

●I-Deburring: Ukuze kuhlanganiswe futhi kusetshenziswe izingxenye, amakhona namaphethelo kungase kudingeke ukuthi kukhishwe imali. Ukuqhunyiswa kobuhlalu bengilazi kungasusa ama-burrs namaphethelo anezimpaphe kuyilapho kuqinisekisa ukuthi ayikho insimbi eyisisekelo ekhishwayo.

●Ukuchama: Ukuchama kwandisa impilo yezingxenye zensimbi ngokulwa nokuqhekeka kwengcindezi nokugqwala.

Ubuhlalu bengilazi bokumaka izindawo zomgwaqo

I-Junda Road yokumaka ubuhlalu bengilazi yenziwe ngesihlabathi sengilazi, ingilazi yemfucuza njengento eluhlaza, ngemuva kokuncibilika kwezinga lokushisa eliphezulu futhi kwakha ubuhlalu bengilazi obuncane, ngaphansi kwesibonakhulu njengento eyindilinga esobala engenambala, ububanzi obuphakathi kwama-microns angama-75 kuya kuma-microns ayi-1400, okwamanje ekukhiqizweni okuyinhloko kwenqubo yobuhlalu bengilazi ekhanyayo iyindlela entantayo yomlilo.

I-Junda Road yokumaka ubuhlalu bengilazi isetshenziswa ikakhulukazi ohlotsheni olujwayelekile lokushisa, uhlobo olushisayo oluncibilikayo lokumaka umgwaqo, olulodwa njengento exutshwe ngaphambili, ingaqinisekisa ukumaka esikhathini sokuphila sokubonisa, okukodwa ekusakazeni kwendawo yokwakha yokumaka, kungadlala umphumela obonakalayo.

Ubuhlalu bengilazi busetshenziswa njengohlobo lokusebenza okuphezulu, izinto eziphilayo ngaphandle kobuhlalu bezingilazi, okwenza ubuhlalu bengilazi bube buthaka isenzakalo sokukhangisa kothuli emoyeni, ngenxa yobuhlalu bengilazi obuqukethe i-ejenti ethile yokuhlanganisa, ithuthukise ubuhlalu namandla ahlangene wokumboza kungavimbela ubuhlalu obuncane bengilazi obuncane uma busebenzisa ukuntanta kwayo, ngenxa yokuthi ikwazi ukuntanta, indawo enkulu, ingakhuphula izinga lokusetshenziswa elingaphezu kuka-30%, manje ubuhlalu bengilazi obukhanyayo sebuyinto engabonakali engenakushintshwa emikhiqizweni yokuphepha emgwaqeni.

Singahlinzeka ngobuhlalu bengilazi ngenkomba ehlukile ye-refractive engu-1.53, 1.72, 1.93 nokunye,Singakwazi futhi ukuhlinzeka ngobuhlalu bengilazi bamazinga ahlukahlukene kazwelonke, noma ngokuya ngokusatshalaliswa kosayizi okunikezwa amakhasimende.

Sihlinzeka ngobuhlalu obujwayelekile bengilazi obulandelayo

Izinga lesiShayina: GB / T 24722 - 2009 No.1, 2, 3

I-Korea Standard: KSL 2521 No.1 no-2

Izinga LaseBrithani: I-BS6088 Ikilasi A no-B

Izinga laseMelika: AASHTO M247 uhlobo 1 bese uthayipha 2

Izinga laseYurophu : EN1423 kanye ne-EN1424

Izinga laseTurkey: TS EN1423

I-New Zealand Standard: NZS2009: 2002

I-Taiwan Standard: CNS

Izinga laseJapane: JIS R3301

I-Australian Standard Australian Standard : A, B, C, D

Ukugaya Ubuhlalu Bengilazi

I-Junda Grinding glass bead iwuhlobo lobuhlalu bengilazi obunosayizi ofanayo, indawo ebushelelezi, ubulukhuni obuphezulu kanye nokuzinza okuhle kwamakhemikhali. Ubuhlalu bokugaya ngokuvamile ubuhlalu bengilazi obunosayizi wezinhlayiyana ezingaphezu kuka-1mm. Azinambala futhi zisobala ngokubukeka futhi ziyindilinga ehlanzekile. Isetshenziswa kabanzi kudayi, upende, uyinki, embonini yamakhemikhali nakwenye i-ejenti ehlakazayo, ukugaya okuphakathi nezinto zokugcwalisa.

Singahlinzeka ngo-0.8 1.2, 1.0, 1.5, 1.5, 2.0, 2.0, 2.5, 2.5, 3.0, 3.0, 3.5 mm usayizi walezi ezimbalwa.

Futhi ngokwezidingo zamakhasimende.

Isicelo

1.Izingxenye zezindiza zesiteleka sobuhlalu, ziqede ukucindezeleka kwazo, zithuthukise amandla okukhathala, zinciphise ukungqubuzana nokuguga;

2.Ukwelashwa kwe-Anodic kanye ne-electroplating ngaphambi kokucubungula, ngaphezu kokuhlanza kungandisa ukunamathela;

3. Insimbi engagqwali workpiece welding pass yokuhlanza kanye nokususwa ukuklwebheka ebusweni kanye nokunye ukucubungula kobuhle;

4. Ukuhlanza nokususwa kwesikhunta sokusika ucingo;

5. Ukwehliswa kwesikhunta senjoloba;

Imingcele Yezobuchwepheshe

| Iphrojekthi | Ikhwalithi | |

| Ukwakheka kwamakhemikhali% | SiO2 | >72% |

| I-CaO | >8% | |

| Na2O | <14% | |

| MgO | >2.5% | |

| I-Al2O3 | 0.5-2.0% | |

| Fe2O3 | 0.15% | |

| Abanye | 2.0% | |

| I-Refractive Index | N≥1.5% | |

| Ukuminyana | 2.4-2.6g/cm3 | |

| Ukusabalalisa usayizi | Usayizi omkhulu ≤5% ngaphansi kosayizi ≤10% | |

| Ububanzi bentambo | 0.03-0.4mm | |

| Ukuqina | 3-5 % | |

| Ukuqina | 6-7 MOHS; Idatha ye-46HRC | |

| Ukuqina okuncane | ≥650kg/cm3 | |

| Isiyingi | Izinga lomjikelezo ≥85% | |

| Ukubukeka | engenambala, ingilazi esobala ngaphandle kokungcola, Eyindilinga futhi ebushelelezi | |

| Isicelo | 1.Ukugaya 2.Upende omaka umgwaqo 3.Ukuqhunyiswa kwesihlabathi | |

| Okuqukethwe Okuholayo | Akukho okuqukethwe okuholayo, finyelela izinga lokuqukethwe Lead laseMelika 16CFR 1303 | |

| Okuqukethwe kwezinto eziyingozi | Ngaphansi kune-American 16CFR 1500 ejwayelekile | |

| Ukuhlolwa komlilo ovuthayo | Amandla omlilo alula, finyelela okujwayelekile kwe-American 16CFR 1500.44 | |

| Okuqukethwe kwensimbi enzima encibilikayo | Okuqukethwe kwensimbi kwesilinganiso sento encibilikayo isilinganiso sesisindo esiqinile akukho ngaphezu kwevelu ehambisanayo ye-ASTM F963 | |

| Iphakheji | ||

| Uhlobo | I-Mesh | I-Micronsm Max(μm) | I-Microns Min(μm) |

| 30# | 20-40 | 850 | 425 |

| 40# | 30-40 | 600 | 425 |

| 60# | 40-60 | 425 | 300 |

| 80# | 60-100 | 300 | 150 |

| 100# | 70-140 | 212 | 106 |

| 120# | 100-140 | 150 | 106 |

| 150# | 100-200 | 150 | 75 |

| 180# | 140-200 | 106 | 75 |

| 220# | 140-270 | 106 | 53 |

| 280# | 200-325 | 75 | 45 |

| 320# | > 325 | 45 | 25 |

Izigaba zemikhiqizo