Ikhwalithi ephezulu yokudutshulwa kwensimbi enokumelana nokugqokwa okuphezulu

Ngenisa

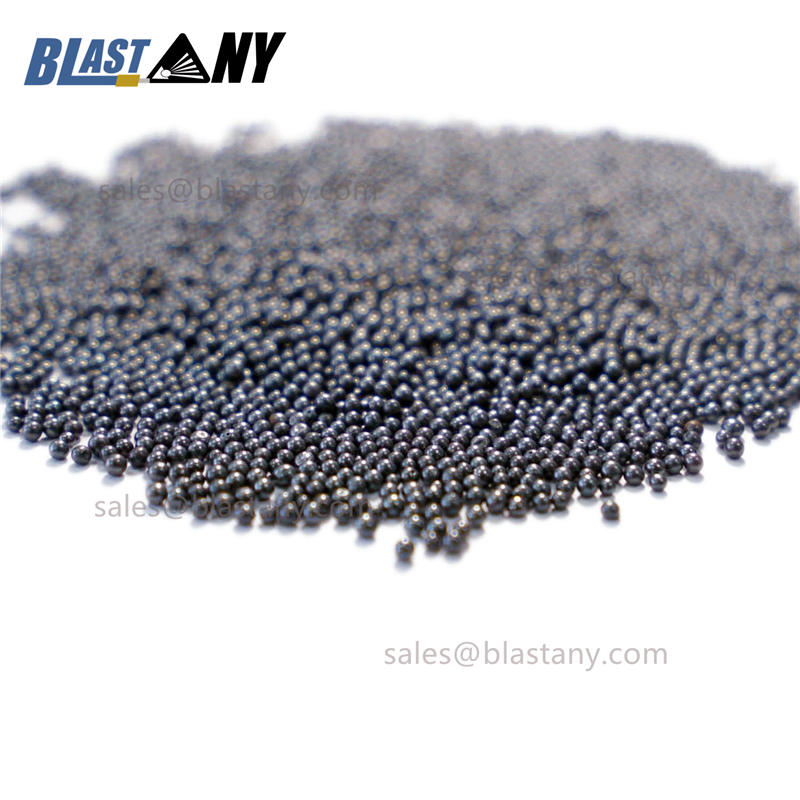

I-Junda Steel Shot ikhiqizwa ngokuncibilikisa izinsalela ezikhethiwe esithandweni sokufakwa kukagesi.Ukwakheka kwamakhemikhali ensimbi encibilikisiwe kuyahlaziywa futhi kulawulwa ngokuqinile nge-spectrometer ukuze kutholwe ukucaciswa Okujwayelekile kwe-SAE.Insimbi encibilikisiwe yenziwe i-athomu futhi iguqulelwe ibe yizinhlayiyana eziyindilinga futhi kamuva icinywe futhi ifudumale enqubweni yokwelapha ukushisa ukuze kutholwe umkhiqizo wokuqina okufanayo kanye ne-microstructure, ehlolwa ngosayizi ngokuya ngencazelo ye-SAE Standard.

I-Junda industrial steel shot ihlukaniswe yaba ezine, isibhamu sensimbi esijwayelekile kazwelonke, esiqukethe i-chromium cast steel shot, amaphilisi ensimbi ekhabhoni ephansi, insimbi engagqwali, okuhlanganisa isibhamu sensimbi kazwelonke esijwayelekile sihambisana ngokuphelele nezimfuneko ezijwayelekile zikazwelonke zokuqukethwe kwesici ukukhiqizwa, kanye nengxenye ye-chromium cast steel shot, kusekelwe ezingeni likazwelonke lamabhola ensimbi, okwengeza inqubo yokuncibilikisa i-ferromanganese ferrochrome ezintweni zokukhiqiza, ezifana no-Owen ophila isikhathi eside;Inqubo yokukhiqiza insimbi ephansi ye-carbon steel kanye ne-standard steel shot shot, kodwa impahla eluhlaza iphansi i-carbon steel, okuqukethwe kwekhabhoni kuphansi;Insimbi engagqwali shot ikhiqizwa atomizing inqubo ukwakha, izinto zokusetshenziswa insimbi engagqwali, 304, 430 insimbi engagqwali nokunye.

Lolu hlobo lokudubula lwenzelwe ukusetshenziswa ekuqhumeni kwesibhamu nasezinqubweni zokuqhuma ngaphansi kwengcindezi yomoya ocindezelwe.Ngokuyisisekelo isetshenziswa ezinsimbi ezingenayo insimbi njenge-aluminium, i-zinc alloys, izinsimbi ezingenasici, ithusi, ithusi, ithusi ...

Ngobubanzi bayo bezigaba, isetshenziselwa ukuhlanza, ukukhipha, ukuhlanganisa, ukuchama nokuqeda izinqubo ezijwayelekile, kuzo zonke izinhlobo zezingxenye, ngaphandle kokungcolisa indawo yayo ngothuli oluyinsimbi oluwohlokayo futhi luguqule umbala wezinsimbi ezilashiwe.ngenqubo yokuguga ye-marble ne-granite.

Isicelo sezimboni

Ukudubula kwensimbi

Isibhamu sensimbi sihlanza isihlabathi sokuphonsa kanye nokushiswa esihlabathini sokubunjwa ukuze kwenziwe indawo engaphezulu ithole ukuhlanzeka okuhle kanye nokuba mahhadladlana okudingekayo, ukuze lokho kube wusizo ekucutshungulweni nasekuhlanganisweni okulandelayo.

I-Cast steel shot yokulungiswa kwendawo ye-Steel plate

I-Cast steel shot ihlanza isikhumba se-oxide, ukugqwala nokunye ukungcola ngokudubula Ukuqhuma, bese kusetshenziswa isicoci se-vacuum noma umoya ocindezelwe ohlanzekile ukuze uhlanze indawo yemikhiqizo yensimbi.

Amashothi ensimbi asetshenziselwa imishini yobunjiniyela

Amashothi ensimbi asetshenziselwa ukuhlanza imishini angasusa ngempumelelo ukugqwala, i-welding slag, nesikhumba se-oxide, aqede ukucindezelwa kokushisela, futhi akhulise amandla okubopha ayisisekelo phakathi kokugqwala kokukhipha ukugqwala nensimbi, ngaleyo ndlela kuthuthukise kakhulu ikhwalithi ye-derust yengxenye eyisipele yemishini yobunjiniyela.

Usayizi wesibhamu sensimbi wokuhlanza amapuleti ensimbi engagqwali

Ukuze kuzuzwe ukwelashwa okuhlanzekile, okukhanyayo, okubabazekayo kokushiswa kwepuleti lensimbi engagqwali, kufanele kukhethwe izinto ezifanele zokugwaza ukuze kususwe isikali endaweni ebandayo egoqwe yensimbi engenasici.

Ngokwamabanga ahlukene, indawo yensimbi engagqwali idinga ukukhetha ama-abrasive ahlukene obubanzi kanye nengxenye ezocutshungulwa.Uma kuqhathaniswa nenqubo yamakhemikhali yendabuko, inganciphisa izindleko zokuhlanza futhi izuze ukukhiqizwa okuluhlaza.

I-steel shot blast media ye-Pipeline anti-corrosion

Amapayipi ensimbi adinga ukwelashwa kwendawo ukuze aqinise ukumelana nokugqwala.Ngokudubula kwensimbi, ukuqhuma kwemithombo yezindaba kuyapholisha, kuhlanza futhi kukhiphe i-oxide futhi okunamathiselwe kufinyelele izinga eliceliwe lokukhipha ukugqwala nokujula okusanhlamvu, hhayi nje ukuhlanza indawo engaphezulu kodwa nokwanelisa ukunamathela phakathi kwepayipi lensimbi nokunamathela, kuzuza umphumela omuhle wokunqanda ukugqwala.

Isibhamu sensimbi siqinisa ukuchama

Izingxenye zensimbi ezisebenza esimweni sokulayisha i-cyclic futhi zingaphansi kwesenzo sokucindezeleka kokuhamba ngebhayisikili zidinga inqubo yokuqinisa ukuchama ukuze kuthuthukiswe impilo yokukhathala.

Cast steel shot Izizinda zohlelo

I-steel shots peening isetshenziswa kakhulu ekuqiniseni ukucutshungulwa kwezingxenye ezibalulekile ezifana nesiphethu se-helical, isiphethu seqabunga, ibha esontekile, igiya, izingxenye zokudlulisela, okuthwala, i-cam shaft, i-axle egobile, induku yokuxhuma nokunye.Lapho indiza ifika, igiya lokuhlala kufanele limelane nomthelela omkhulu elidinga ukwelashwa kokuchama okudutshulwa njalo.Amaphiko nawo adinga ukwelashwa kokukhululwa kokucindezeleka ngezikhathi ezithile.

Imingcele Yezobuchwepheshe

| Iphrojekthi | Amazinga Kazwelonke | Ikhwalithi | |

| Ukwakheka kwamakhemikhali% | C | 0.85-1.20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Ukuqina | isibhamu sensimbi | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Ukuminyana | isibhamu sensimbi | ≥7.20 g/cm3 | 7.4g/cm3 |

| I-Microstructure | I-Tempered Martensite noma i-Troostite | Inhlangano Ehlanganisiwe ye-Martensite Bainite Composite | |

| Ukubukeka | I-Spherical Izinhlayiya ezingenalutho<10% Izinhlayiya zoqhekeko <15% | I-Spherical Izinhlayiya ezingenalutho<5% Izinhlayiya zoqhekeko<10% | |

| Uhlobo | I-S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Ukupakisha | Ithani ngalinye ku-Pallet ehlukile futhi ithani ngalinye lihlukaniswe ngamaphakethe angama-25KG. | ||

| Ukuqina | 2500 ~ 2800 izikhathi | ||

| Ukuminyana | 7.4g/cm3 | ||

| Ububanzi | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Izinhlelo zokusebenza | 1. Ukuhlanza ukuqhuma: Kusetshenziselwa ukuhlanza ukuqhuma kokusakazwa, ukufakela, ukubumba;ukususwa kwesihlabathi kokusakazwa, ipuleti lensimbi, uhlobo lwensimbi H, isakhiwo sensimbi. 2. Ukususwa kokugqwala: Ukususwa kokugqwala kokubunjwa, ukubumba, ipuleti lensimbi, uhlobo lwensimbi H, isakhiwo sensimbi. 3. Ukuchama okudutshulwa: Ukuvula isibhamu, izingxenye eziphathwe ukushisa. 4. Ukuqhuma kwesibhamu: Ukudubula kwensimbi yephrofayili, ibhodi lomkhumbi, ibhodi lensimbi, impahla yensimbi, isakhiwo sensimbi. 5. Ukwelashwa kwangaphambili: Ukwelashwa kwangaphambili kwendawo, ibhodi lensimbi, insimbi yephrofayili, isakhiwo sensimbi, ngaphambi kokudweba noma ukumboza. | ||

Usayizi Wokusatshalaliswa Kwezinsimbi Zensimbi

| I-SAE J444 Standard Steel shot | Isikrini No. | In | Usayizi wesikrini | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | I-S170 | I-S110 | S70 | |||

| KONKE kudlule | 6 | 0.132 | 3.35 | |||||||||||

| Konke Kudlula | 7 | 0.111 | 2.8 | |||||||||||

| 90% min | Konke Kudlula | 8 | 0.0937 | 2.36 | ||||||||||

| 97%imizuzu | 85%imizuzu | Konke Kudlula | Konke Kudlula | 10 | 0.0787 | 2 | ||||||||

| 97%imizuzu | 85%imizuzu | 5% ubuningi | Konke Kudlula | 12 | 0.0661 | 1.7 | ||||||||

| 97%imizuzu | 85%imizuzu | 5% ubuningi | Konke Kudlula | 14 | 0.0555 | 1.4 | ||||||||

| 97%imizuzu | 85%imizuzu | 5% ubuningi | Konke Kudlula | 16 | 0.0469 | 1.18 | ||||||||

| 96%imizuzu | 85%imizuzu | 5% ubuningi | Konke Kudlula | 18 | 0.0394 | 1 | ||||||||

| 96%imizuzu | 85%imizuzu | 10% ubuningi | Konke Kudlula | 20 | 0.0331 | 0.85 | ||||||||

| 96%imizuzu | 85%imizuzu | 10% ubuningi | 25 | 0.028 | 0.71 | |||||||||

| 96%imizuzu | 85%imizuzu | Konke Kudlula | 30 | 0.023 | 0.6 | |||||||||

| 97%imizuzu | 10% ubuningi | 35 | 0.0197 | 0.5 | ||||||||||

| 85%imizuzu | Konke Kudlula | 40 | 0.0165 | 0.425 | ||||||||||

| 97%imizuzu | 10% ubuningi | 45 | 0.0138 | 0.355 | ||||||||||

| 85%imizuzu | 50 | 0.0117 | 0.3 | |||||||||||

| 90%imizuzu | 85%imizuzu | 80 | 0.007 | 0.18 | ||||||||||

| 90%imizuzu | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Izinyathelo Zokukhiqiza

Impahla eluhlaza

Ukubumba

Ukomisa

Ukuhlola

Ukukhetha

Ukuthukuthela

Ukuhlola

Iphakheji

Izigaba zemikhiqizo