Isibhamu sensimbi engagqwali ngobuchwepheshe bokwenza i-atomization

Inkambu yohlelo lokusebenza

1.Ukuqedwa kobuso be-aluminium zinc die casting kanye nokuhlanzwa kwendawo yokusakazwa kwesihlabathi se-aluminium. ukufafaza nokupholishwa kwendawo yemabula eyenziwe ngemabula. Ukuhlanza nokuqedwa kwe-high alloy steel casting surface oxide scale, ibhulokhi yenjini ye-aluminium alloy nezinye izingxenye ezinkulu ze-die casting, ukwelashwa kwe-marble surface effect kanye nokwelashwa kwe-antiskid.

2.I-Aluminium zinc die casting, ukuhlanzwa kwendawo yokusakazwa okunembayo, ukuqina kwendawo ngaphambi kokumbozwa okukhethekile, ukucwebeliswa kwesifutho se-aluminium okucolisisiwe ukuze kususwe imigqa yokukhipha ngaphezulu, ukucwenga ukucwenga kwesifutho sepayipi le-aluminium yethusi, kanye nokucwengisiswa kwesifutho okucolisisiwe kwesiqukathi sensimbi engagqwali kanye nevalvu.

3. Hlanza amathuluzi okusakaza abandayo, i-chromium plating iyafa ukuze ifake amafa namathayi, vuselela ikhava yepompo yeshaja yenjini yemoto, qinisa igiya elinemba kanye nentwasahlobo yesiqalisi, futhi ufafaze ukupholisha ubuso besiqukathi sensimbi engagqwali.

4.I-aluminium zinc die casting, ibhokisi lenjini yesithuthuthu, ikhanda lesilinda, i-carburetor, igobolondo lephampu yenjini, ipayipi lokungena, ilokhi yemoto. Ingaphezulu lephrofayili yesondo elinomfutho ophansi kufanele ihlanzwe futhi iqedwe ngaphambi kokupenda. Ukuqedwa kobuso nokuhlanza izingxenye zokugxiviza zensimbi engenasici ye-aluminium yethusi, izingxenye zensimbi engenasici, njll.

Imingcele Yezobuchwepheshe

| Iphrojekthi | 304 Ikhwalithi | 430 Ikhwalithi | |

| Ukwakheka kwamakhemikhali% | C | 0.08-1.0 | <0.2 |

| Si | 0.4-1.2 | <1.5 | |

| Mn | 0.35-1.2 | 0.8-1.2 | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 | 15-17 | |

| Ni | 5-8% | 0 | |

| Ukuqina | HRC40-50 | HRC35-50 | |

| Ukuminyana | 7.00 g/cm3 | ||

| I-Microstructure | i-austenitic | I-Ferrite | |

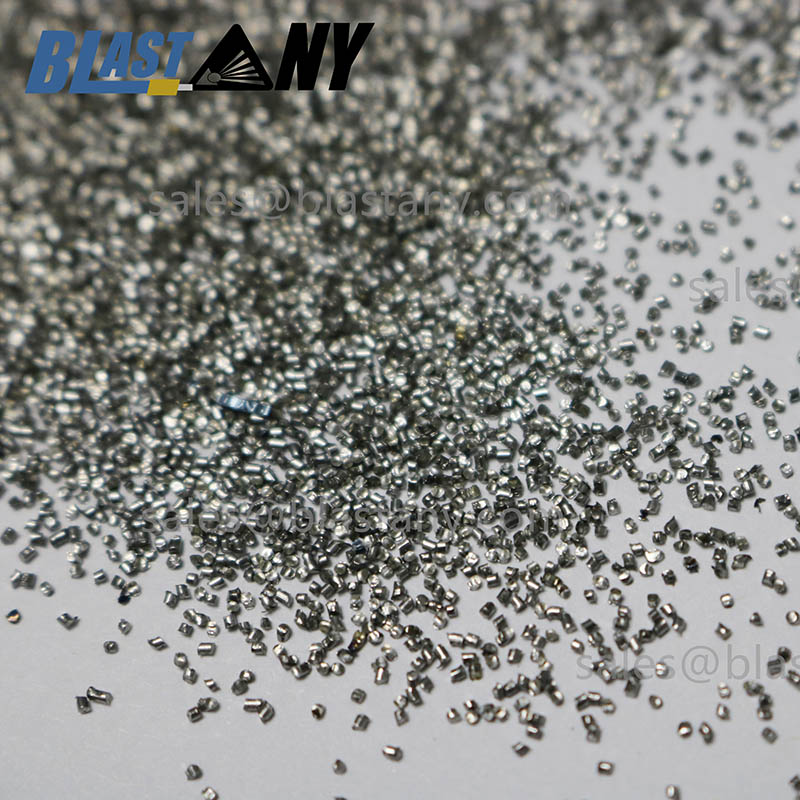

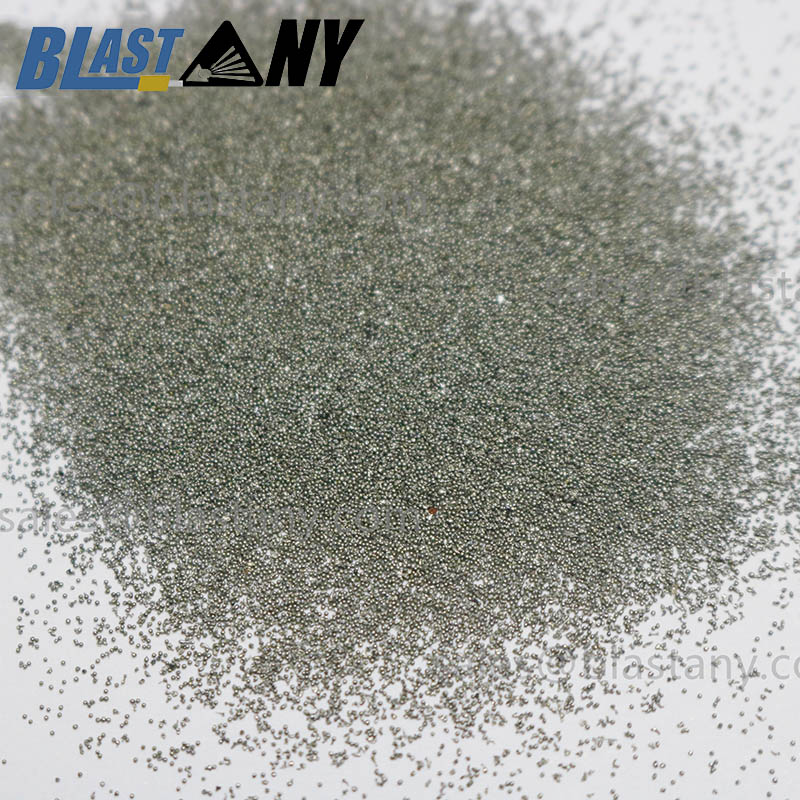

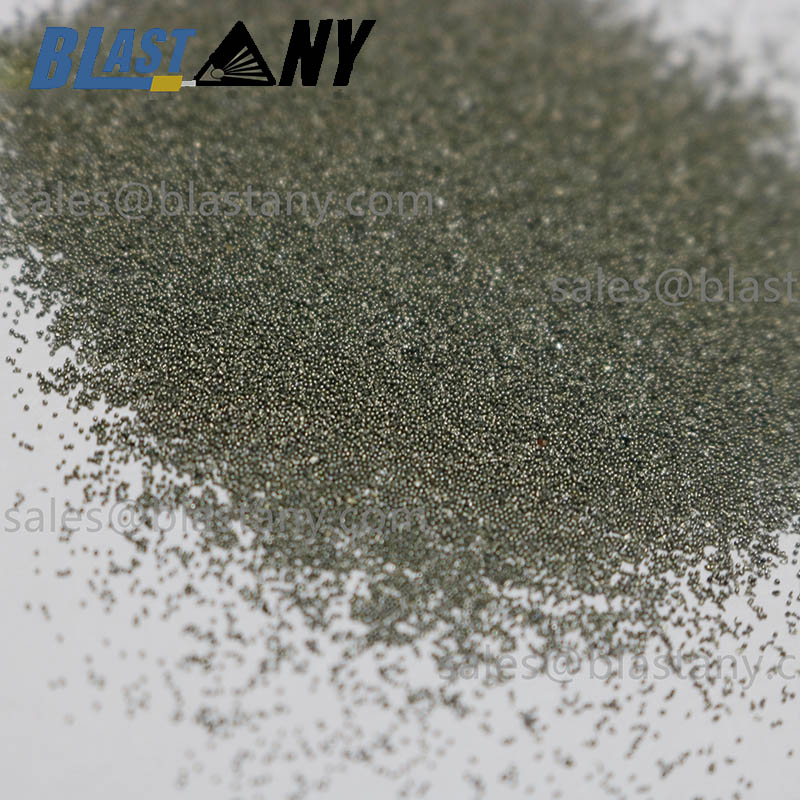

| Ukubukeka | I-Spherical Izinhlayiya ezingenalutho=0% Izinhlayiya ezingenalutho=0% | ||

| Uhlobo | 14-18# / 16-20# / 20-25# / 25-30# / 30-40# / 40-70# / 70-140# / 140-270# | ||

| Ukupakisha | Ithani ngalinye ku-Pallet ehlukile futhi ithani ngalinye lihlukaniswe ngamaphakethe angama-25KG. | ||

| Ukuqina | 27000 ~ 28000 izikhathi | ||

| Ukuminyana | 7.0g/cm3 | ||

| Isicelo | Ngokuyinhloko isetshenziselwa ukuchithwa kanye nokuqedwa kwendawo ye-aluminium die casting, i-zinc alloy die casting kanye ne-magnesium alloy die casting; ukuqedwa kwendawo yokubunjwa okunembayo, ukubunjwa kwensimbi engagqwali kanye ne-landscape block; ukwenza ingilazi, ukuhlanzwa kwendawo kanye nokwelashwa kwangaphambili okuhlukahlukene kwesikhunta se-die casting. | ||

Isicelo

| UHLOBO | Ububanzi obunconywayo bokusebenzisa |

| 14-18# | Hlanza amathuluzi okusakaza abandayo, i-chromium plating iyafa ukuze ifake amathayi, lungisa ikhava yephampu yeshaja yenjini yemoto, qinisa igiya elinemba kanye nentwasahlobo yesiqalisi, futhi ufafaze ukupholisha okungaphezulu kwesiqukathi sensimbi engagqwali. |

| 16-20# | I-Aluminium zinc die casting, ukuhlanzwa kwendawo yokusakazwa okunembayo, ukuqina kwendawo ngaphambi kokumbozwa okukhethekile, ukucwebeliswa kwesifutho se-aluminium okucolisisiwe ukuze kususwe imigqa yokukhipha ngaphezulu, ukucwenga ukucwenga kwesifutho sepayipi le-aluminium yethusi, kanye nokucwengisiswa kwesifutho okucolisisiwe kwesiqukathi sensimbi engagqwali kanye nevalvu. |

| 20-25# | I-aluminium zinc die casting, ibhokisi lenjini yesithuthuthu, ikhanda lesilinda, i-carburetor, igobolondo lephampu yenjini, ipayipi lokungena, ilokhi yemoto. Ingaphezulu lephrofayili yesondo elinomfutho ophansi kufanele ihlanzwe futhi iqedwe ngaphambi kokupenda. Ukuqedwa kobuso nokuhlanza izingxenye zokugxiviza zensimbi engenasici ye-aluminium yethusi, izingxenye zensimbi engenasici, njll. |

| 25-30# | I-aluminium zinc die casting surface finishing, i-aluminium casting sand casting surface yokuhlanza. Ingaphezulu lemabula yokwenziwa liyafuthwa futhi lipholishwe. |

| 30-40# | Ngokungeziwe kumsebenzi we-wg40, ingaphezulu lensimbi engagqwali libushelelezi futhi lilungile. Ukwehliswa kokwelashwa kwe-alloy steel forgings. Umphumela wokuqeda imabula yokwenziwa kanye nokwelashwa kwe-antiskid. |

| 40-70# | I-high alloy steel casting surface oxide isikhumba, ibhulokhi yenjini ye-aluminium alloy nezinye izingxenye ezinkulu ze-die casting zokuhlanza nokuqeda, ukwelashwa komphumela wemabula kanye nokwelashwa kokulwa nokushushuluza. |

| 70-140# 140-270# | Ingaphezulu lokusansimbi elibunjiwe liyabola ngaphambi kokumbozwa, ihabhu lamasondo emoto, ukulashwa kwamagobolondo enjini, imikhiqizo yegwadle kanye nezinyathelo zemabula ze-roughening kanye nokwelashwa okulwa nokushushuluza. |

Ubumbudumbudu

| IsikriniNO. | Usayizi wesikrini mm | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 | 70-140 | 140-270 |

| 14 | 1.4 | 0.0555 |

|

|

|

|

|

|

|

|

| 16 | 1.18 | 0.0469 |

|

|

|

|

|

|

|

|

| 18 | 1 | 0.0394 |

|

|

|

|

|

|

|

|

| 20 | 0.85 | 0.0331 |

|

|

|

|

|

|

|

|

| 25 | 0.71 | 0.0278 |

|

|

|

|

|

|

|

|

| 30 | 0.6 | 0.0234 |

|

|

|

|

|

|

|

|

| 35 | 0.5 | 0.0197 |

|

|

|

|

|

|

|

|

| 40 | 0.425 | 0.0165 |

|

|

|

|

|

|

|

|

| 50 | 0.3 | 0.0117 |

|

|

|

|

|

|

|

|

| 70 | 0.212 | 0.0083 |

|

|

|

|

|

|

|

|

| 100 | 0.15 | 0.0059 |

|

|

|

|

|

|

|

|

| 140 | 0.106 | 0.0041 |

|

|

|

|

|

|

|

|

| 270 | <0.05 | <0.0019 |

|

|

|

|

|

|

|

|

Izigaba zemikhiqizo