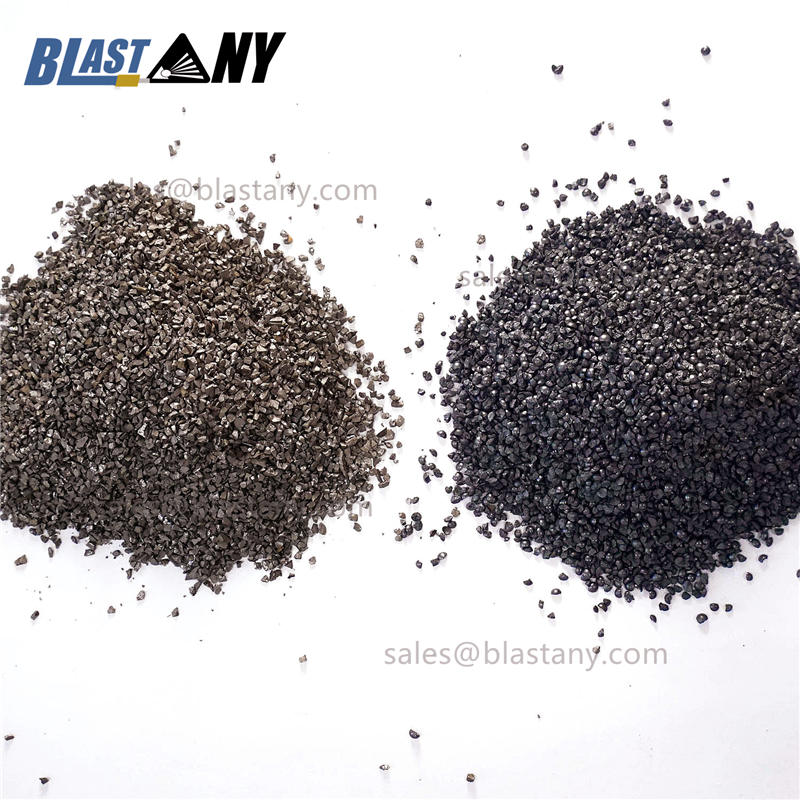

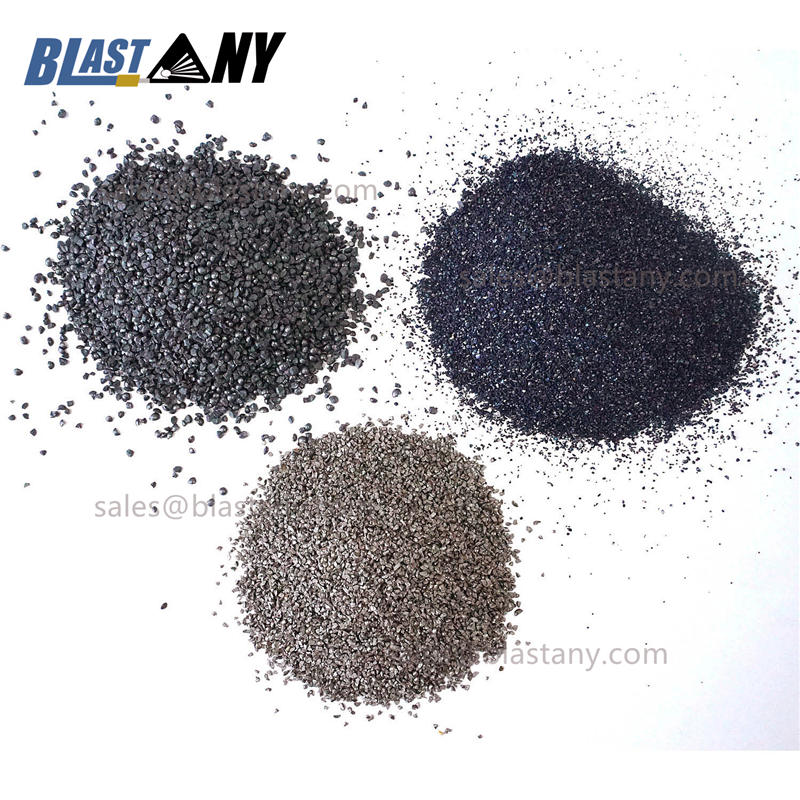

Igrit yensimbi enezincazelo ezijwayelekile ze-SAE

I-Junda Steel grit yobulukhuni obuhlukahlukene

1.Igrit yensimbi ye-GP: Lokhu kuhuzuka, lapho kusanda kwenziwa, kukhonjisiwe futhi kunezimbambo, futhi imiphetho namakhona ayo afinyezwa ngokushesha ngesikhathi sokusetshenziswa. Ifaneleka ngokukhethekile ukukhishwa kwangaphambili kwensimbi yokususwa kwe-oxide.

2. I-GL grit: Nakuba ubulukhuni be-GL grit buphakeme kune-GP grit, isalahlekelwa imiphetho namakhona ngesikhathi senqubo ye-sandblasting futhi ifaneleka ngokukhethekile ukunakekelwa kwangaphambili kokukhipha isikali se-oxide endaweni yensimbi.

3.Isihlabathi sensimbi ye-GH: Lolu hlobo lwesihlabathi sensimbi lunokuqina okuphezulu futhi luzohlala lugcina imiphetho namakhona ekusebenzeni kokuqhunyiswa kwesihlabathi, okusebenza kahle kakhulu ekwakheni izindawo ezivamile nezinoboya. Lapho isihlabathi sensimbi ye-GH sisetshenziswa ekusebenzeni komshini wokudubula, izidingo zokwakha kufanele zicatshangelwe ngokukhetha izici zentengo (njengokwelashwa kwe-roll emshinini wokugoqa obandayo). Le grit yensimbi isetshenziswa kakhulu kumishini yokuvula isibhamu somoya.

Isicelo sezimboni

Steel grit Cleaning

Isibhamu sensimbi nensika kusetshenziswa ekuhlanzeni izinhlelo zokusebenza zokususwa kwezinto ezixegayo endaweni yensimbi. Lolu hlobo lokuhlanza luvamile embonini yezimoto (amabhulokhi ezimoto, amakhanda amasilinda, njll.)

Ukulungiswa kobuso bensimbi

Ukulungiswa kwendawo kunjengochungechunge lwemisebenzi ehlanganisa ukuhlanzwa nokuguqulwa komzimba kwendawo. Ukudubula kwensimbi kanye nensika kusetshenziselwa inqubo yokulungisa indawo yokuhlanza izindawo zensimbi ezimbozwe ngesikali sokugaya, ukungcola, ukugqwala, noma upende kanye nokulungisa ubuso bensimbi njengokwakha ukuhwashala ukuze kusetshenziswe kangcono upende nokunamathela. Amashothi ensimbi ngokuvamile asetshenziswa emishinini yokudubula.

Insimbi yensimbi Ukusika Itshe

Igrit yensimbi isetshenziselwa ukusika amatshe aqinile, njenge-granite. Igrit isetshenziswa kumafreyimu amakhulu anama-multi-blade asika amabhlogo egwadle abe izingcezu ezincane.

Insimbi yensimbi Shot ichama

I-shot peening ukushaya okuphindaphindiwe kwendawo yensimbi ngama-hard shot particles. Le mithelela eminingi ikhiqiza ukuwohloka endaweni yensimbi kodwa futhi ithuthukisa ukuqina kwengxenye yensimbi. Imidiya esetshenziswe kulolu hlelo lokusebenza iyindilinga kune-angular. Isizathu siwukuthi amashothi ayindilinga amelana kakhulu nokuphuka okwenzeka ngenxa yomthelela omangalisayo.

Igrit yensimbi yokuqhunyiswa kwesihlabathi

Ikhwalithi yegrit yensimbi ye-Carbon esetshenziselwa ingxenye yomzimba yokuqhunyiswa kwesihlabathi ithinta ngokuqondile ikhwalithi kanye nenani eliphelele lezindleko ngokuya ngokusebenza kahle kokuqhunyiswa kwesihlabathi, ukunamathela kwebhande, ukudweba, amandla e-kinetic kanye nokusetshenziswa kwe-abrasive. Ngokukhishwa okusha kwe-coating protection performances standard (PSPC), kunesicelo esiphezulu sekhwalithi yokuqhunyiswa kwesihlabathi esihlakaniphile. Ngakho-ke, ikhwalithi yegrit ye-cast Steel ibaluleke kakhulu ekuqhumeni kwesihlabathi.

I-angular shot yesitsha se-sandblasting

Isihlabathi sensimbi eyindilinga esiqhuma emzimbeni webhokisi lesiqukathi ngemva kokushisela. Hlanza ijoyinti elishiselwe futhi ngesikhathi esifanayo ubangele ukuthi indawo yomzimba webhokisi ibe nobuhwaqaqe obuthile futhi yandise umphumela wokupenda wokunqanda ukugqwala, ukuze ukwazi ukusebenza isikhathi eside phakathi kwemikhumbi, i-chassis, imoto yezimpahla kanye nezimoto zikaloliwe.Intengo yethu yegrit yensimbi inengqondo.

I-Grit spherical ye-Sandblasting yemishini kagesi wasendle

Umkhiqizo kagesi wasendle unesicelo esiqondile sokuqina nokuhlanzeka kokulungiswa kwendawo .Ngemva kokwelashwa kwe-angular steel grit surface, kufanele babhekane nezinhlobo zezinguquko zesimo sezulu ngaphandle isikhathi eside. Ngakho-ke, ukuqhuma kwesihlabathi esiyisiyingi esiyindilinga kungaphezulu kubaluleke kakhulu.

Imingcele Yezobuchwepheshe

| SAE | Isicelo |

| G-12 | Ukuqhumisa/ukwehlisa insimbi esakhiwe phakathi kuya kwenkulu, insimbi eyinsimbi, izingcezu ezifojiwe, ipuleti lensimbi nezingcezu zomsebenzi ezinamathiselwe ngerabha. |

| G-18 | Itshe lokusika/lokugaya; Izingcezu zomsebenzi zenjoloba eziqhumayo; |

| G-50 | Intambo yensimbi eqhumayo, isipanela, ipayipi lensimbi ngaphambi kwenqubo yokupenda; |

Izinyathelo Zokukhiqiza

Impahla eluhlaza

Ukuthukuthela

Ukuhlola

Iphakheji

Izigaba zemikhiqizo